pag.7

techniques for energy saving

LB1203

MULTICALOR 300.1÷400.1

AIR ADJUSTMENT

+

- -

Part. 1

Part. 2

Part. 3

-

+

-

COMMUTATORE

0

AUTO

0 = bloccaggio degli apparati per il

funzionamento in una posizione intermadia

= funzionamento alla massima potenza

= funzionamento alla minima potenza

AUTO = funzionamento automatico

operating elements locked in an intermediate

position

operation on maximum capacity

operation on minimum capacity

automatic operation

SELECTOR

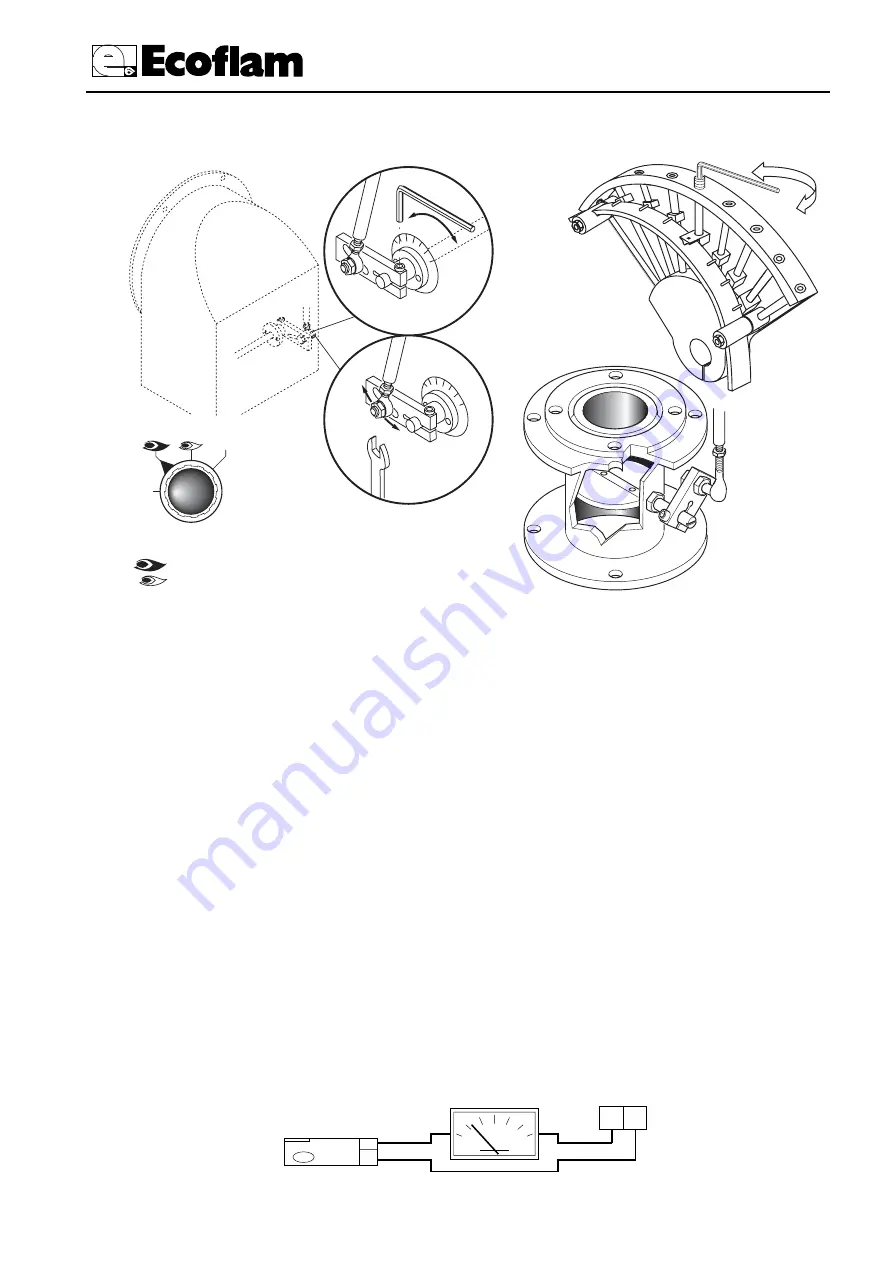

ADJUSTING THE MINIMUM CAPACITY OF THE BURNER – AIR and GAS

Position the selector placed on the control panel on position 2 and proceed as follows:

Adjust the minimum gas flow rate using a suitable wrench, turn the butterfly valve until you reach the correct gas

flow, as established by analyzing the combustion process.

ADJUSTING THE MAXIMUM CAPACITY OF THE GAS

Position the selector, situated on the control panel, on position 1 and proceed as follows:

Adjusting the maximum gas flow rate (see figure on solenoid valve adjustments) or adjust the gas pressure in the

governor.

ADJUSTING THE MAXIMUM AIR FLOW RATE

Adjusting the maximum air flow rate (see figure, detail 2). Loosen the nut holding the air damper transmission rod;

The correct air flow as established by analyzing the combustion process.

ADJUSTING THE INTERMEDIATE BURNER CAPACITY

Using the selector, start the servomotor (closing or opening) and position on 0 to stop the stroke; the adjustment is

made as outlined below. Repeat the operation for the other cam points.

Adjustment the intermediate gas flow rates (see figure, detail 3): - using a suitable Allen wrench, change the position

of the cam guide blade; if you screw it down, the flow rate is reduced; if you unscrew it, the flow rate increases.

22 23

LANDIS

LFL 1.622

Fotocellula

min 70

µ

A

Microamperometro

fondo scala 1000

µ

A

FLAME DETECTION SYSTEM CHECK

PHOTORESISTOR

Microamperometer

full scale 1000 µA