6.0 SYSTeM aDJUSTMeNTS

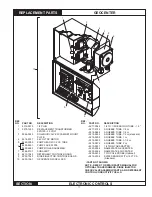

DETERGENT CONTROLLER P.C. BOARD

Figure 6-1

6.1 cell/Sensor Selection

Ensure jumper JP2 on the detergent controller PC board is

set properly for the corresponding cell/sensor. For S-2000

sensor operation, the jumper should only be installed on

ONE pin of JP2.

For two-pole probe operation, the jumper should be installed

on the right two pins of JP2, labeled "S26".

6.2 concentration adjustment

Concentration versus Conductivity

when the detergent is dissolved in the wash tank, it produces

a certain

concentration

of product. A given concentration

of product will, in turn, produce a corresponding

conductiv-

ity

signal that can be measured by the cell/sensor used by

the detergent controller. The controller attempts to reach

a desired solution concentration by using the conductivity

signal to control when to feed detergent product into the

wash tank.

However, the actual conductivity signal measured in the wash

tank can vary significantly due to natural conductivity in the

wash tank water. The detergent controller cannot distinguish

between the conductivity signal produced by the water and

that produced by the dissolved detergent.

For this reason, the setting of the TITRATION DIP switch

should be viewed as a starting point that may require adjust-

ing once the wash tank is titrated.

Titration Adjustment

Adjustment of the wash tank concentration is done using

the six position TITRATION DIP switch on the detergent

controller PC board. The individual positions on this DIP

switch are labeled 1 through 6. Sliding a position to the left

will turn that position ON. Sliding a position to the right will

turn that position OFF. when a position is ON, the detergent

controller will add detergent to the wash tank according to

the following table:

SWITCH

POSITION ON

1

2

3

4

5

6

APPROX. #

GeO DROPS

2

4

8

16

32 64

APPROX. #

STANDARD DROPS 1

2

4

8

16 32

when multiple positions are ON, the detergent controller

will add all positions together to achieve the desired tank

concentration.

Example using Standard Drops:

1. Assume a desired tank concentration of 14 standard

drops is required. Start by turning positions

1

and

2

and

3

ON

. (2 + 4 + 8 equals 14)

2. Allow the detergent controller to feed until the 100%

LeD begins flashing rapidly. Immediately titrate the tank

TITRATION ADJuSTMENT

SONALERT

®

ALARM DE-

LAY ADJuSTMENT

SONALERT

®

ALARM VOLuME

ADJuSTMENT

CeLL/SeNSOR

SELECTION

FEED ADJuST PO-

TENTIOMETERS

Note: JP1 and JP2

jumpers in "open"

position.

solution.

3. If the actual titration measurement is only 10 drops, the

wash tank water conductivity is already adding a read-

ing of 4 drops to the measurement. The TITRATION

DIP switch must be readjusted to a setting of 18 to add

additional detergent to the tank.

4. Turn positions

2

and

3

OFF and position

4

ON. This

results in positions

1

and

4

ON. (2 + 16 equals 18)

5. Repeat step 2. This should now provide the desired

concentration.

6.3 feed adjustment potentiometers

When the wash tank concentration is between 80% to 100%

of the set point, the dispenser will provide an “on-off” pulse

feed mode to control overshoot.

These potentiometers determine the duration of the “on-off”

pulses. This allows for minimum overshoot dependent upon

the detergent dispensing rate,

refer to Figure 6-1.

The normal setting (as factory set) is both pots being in the

full counter-clockwise position, providing for a 1 second “on”

pulse and a 1 second “off” pulse. This is desirable for most

operating conditions.

These are adjustable up to a maximum of 12 seconds. If

the detergent delivery rate is very slow, such as might be

encountered with low feed water temperature to the reservoir,

it may be desirable to increase the “on” pulse time.

In a very large wash tank, it may be desirable to increase

the “off” to allow the detergent to disperse evenly throughout

the wash tank before further feeding occur.