6" MIN (uS)

30 cm (INT'L)

w

AT

ER FLOw

H

D

W

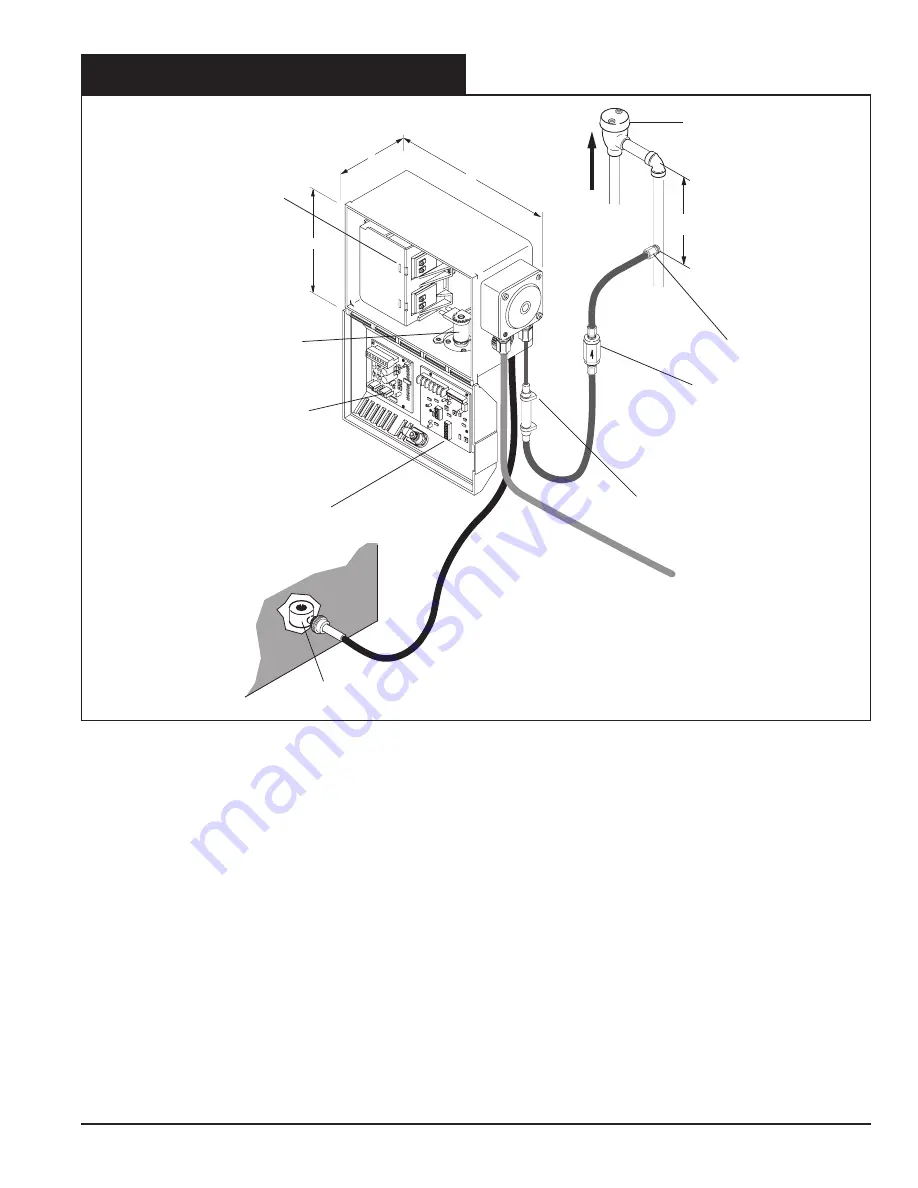

3.0 SpecIfIcaTIONS

System Diagram

An injection fitting assembly requires a 1/8 NPT tap into the

final rinse line.

3.4 electrical requirements

The GeoCenter operates on a 24 volt AC, 50/60Hz power

source supplied through two 30 VA transformers. The

transformer primaries can be either 115 or 230 volts. One

transformer provides power for the detergent control and

the other provides power for the rinse injector.

If the primary voltage is 440 volts, two separate, externally

mounted transformers will be required. The 24 volt secondary

wiring of one transformer will be connected directly to the

Detergent Controller P.C. Board. The 24 volt secondary of the

second transformer will be connected directly to the Rinse

Speed Control P.C. Board. Both the internal transformers

can be removed when wiring for a 440 volt installation.

IMPORTANT: Make sure the power source is turned off

3.1 Dimensions

• Height (H): 7-5/8" (19.4 cm)

• Width (W): 11-3/8" (28.9 cm)

• Depth (D): 6-3/8" (16.2 cm)

• Weight: 12 LB. (5.4 kg)

3.2 access requirements

Mounting location must allow cabinet cover to swing down

180° for adequate installation and service. Allow room on

the right side to service the peristaltic pump, and on the left

for electrical service.

3.3 product pickup and Discharge

The pick-up tubing, 1/8" (3.2 mm) Polyflo, must not

exceed 10' (3 meters) in length. The maximum discharge

tubing length of 150' (45 meters) will accommodate

remote installations of the GeoCenter. If tubing length

exceeds 50' (15 meters) the tubing must be replaced with

1/4" (6.3 mm) Polyflo tubing to minimize back pressure.

SOLENOID VALVE

(REFER TO FIGuRE 4-4 ON

PAGE 6.)

DETERGENT CONTROLLER

P.C. BOARD

RINSE SPEED

CONTROL P.C. BOARD

TRANSFORMER ASSEMBLY

(REFER TO FIGuRE 5-2 ON

PAGe 8.)

INJECTION POINT

TO GEOSYSTEM

RINSE DISPENSER

WASHTANK

S-2000

SENSOR

VACUUM BReAKeR

VISuAL FLOw INDICATOR

CHeCK VALVe