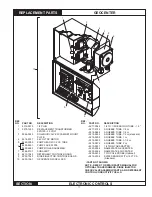

Figure 4-1

4.0 INSTaLLaTION prOceDUreS

4.1 pre-planning the Installation

There is no substitute for planning the installation prior to

beginning the work, minutes in planning may save hours in

installation time. The following items should be taken into

consideration before installing the GeoCenter:

• Allow visual displays on the front of the cabinet to be in

full view of the operator.

• Permit shortest possible tube, wire, and conduit

lengths

• Provide accessibility for adjustments and servicing.

• Provide as much protection from moisture/steam and

heat as possible.

The following items should be taken into consideration before

installing the Sensor. The sensor should be located in an

area of the wash tank that provides:

• A minimum 2" (5 cm) from the tank bottom, sidewall,

overflow piping, etc.

• As far as possible (2" minimum) (5 cm) from heater

elements or coils.

• Protection from physical hazards.

• For constant submersion of all parts of the sensor in

the wash water. This is a particular concern on shallow

tank machines.

NOTE: The S-2000 Sensor is provided with a 12' cable

and mounts from the inside of the washtank. Sufficient

clearance on the inside is required to allow insertion/

removal of the sensor.

NOTE: A S-2000 sensor with 24' cable is available where

necessary (9212-2316).

4.2 Installing the Transformer

1. Mount the plastic transformer enclosure assembly into

the plastic GeoCenter enclosure.

(Refer to Figure 4-1)

.

Attach to plastic GeoCenter enclosure with 8-32 x 5/16

screw in kit bag. Ground using green/yellow wire.

4.3 Mounting the Geocenter

1. Mount the GeoCenter cabinet to the wall using the

supplied screws, washers and plastic wall anchors. The

GeoCenter cabinet may also be installed on top of the

dish machine, using the universal mounting brackets,

and may be the preferred location in some installations.

The installation should be secure, neat and square,

refer to

Figure 4-1.

4.4 Mounting Sensor in Wash Tank

Review Item 4.1, Pre-planning the Installation,

before the

installation begins.

IMPORTANT: Before drilling the hole check for

obstructions both inside and outside of the wash

tank.

1. Cut a 7/8" (22 mm) hole into the wash tank wall.

SCREw

WASHeR

WALL ANCHOR

2.

Properly DEBURR the hole.

3. Attach the sensor connector to the tank using the pro-

vided metal lock nut and the stainless steel and rubber

washers on both the inside and outside surfaces of

the tank wall. Regardless of which sensor is used, the

packing nut end of the tank connector must be on the

outside of the machine wall,

refer to Figure 4-2.

4. Position the sensor by sliding it through the connector

opening and tightening the packing nut.

4.5 Geosystem Detergent Dispenser

Installation

1. Install the desired Geosystem Detergent Dispenser

following the installation instructions provided for that

unit.

4.6 VaNGUarD Wash Max Installation

1. Install the desired VANGuARD wash Max following the

installation instructions provided for that unit.

S-2000 SENSOR

SENSOR

CABLE

PACKING NUT

PACKING GLAND

Figure 4-2