417101634_Lubo-DryExx_Advanced

- 35 -

Rev. 07-01.15

4.3

Lubrication Function Description

When a lubrication circuit is activated a diaphragm compressed air pump is started and

the pressure of the conveyor belt lubricant in the system is raised. Following the fixed

run up period, the lubrication circuit valve opens for an adjustable period of time and the

conveyor belt lubricant is applied via the nozzle system to the conveyor belt tracks.

The lubricant pressure required is adjusted by the compressed air filter regulator in the

metering station. For the best possible spray pattern, the pressure at the nozzles should

be between 2 and 2.5 bar.

Once the spraying process is complete, the pump is stopped, the lubrication circuit valve

closes and at the same time a release valve in the metering station opens, which

depressurises the whole supply and nozzle system.

The pressure is released by a return pipe through a suction lance adaptor with a non-

return valve in the return connection back into the hopper reservoir. The non-return valve

prevents the circuit from emptying.

An empty report is generated by a float contact in the suction lance and processed and

displayed at the control unit. The applicator pump used is dry-running protected and self-

priming.

If the average pressure reaches the pre-set control air pressure, the pump switches off

automatically.

4.4

Configuration

DryExx®

A diaphragm compressed air pump supplies the conveyor belt lubricant, via a suction

lance with an empty detector unit, to the lubrication circuit with the nozzle fittings.

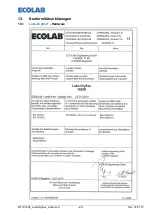

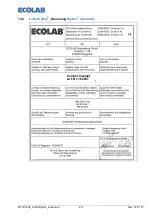

4.4.1 Metering pump

Pneumatically driven diaphragm pump with a supply capacity of between 0 and 25 litres

per minute dependent upon control and backpressure. Control of the pump is by a 3/2-

way solenoid valve. The supply and pressure in the system is set according to the

control air pressure.

4.4.2 Compressed air unit

Consists of a filter regulator with a flange mounted 3/2-way solenoid valve. The control

air pressure of the pump is set by means of the filter regulator and the solenoid valve

switches the control air on or off.

4.4.3 Pressure release valve

A pneumatically controlled 2/2-way diaphragm valve is fitted to the pressure side by a T-

piece. The control takes place via the connected 3/2-way solenoid. By means of the

diaphragm valve, the system is reduced to a pressure of 0.8 bar, when the lubrication

circuits are not activated.

4.4.4 Suction lance

The pump supplies the conveyor belt lubricant via a suction lance fitted as standard. The

suction lance is fitted with a float contact for to detect and provide a warning if empty.

The signal is processed in the control unit and the installation goes into fault mode until

the hopper reservoir is changed. The container adaptor supplied ensures firm seating of

the suction lance into the container and enables the connection of the return pipe from

the pressure release system.