Self

-

loading Bale Wrapper EW

-

1800T

63

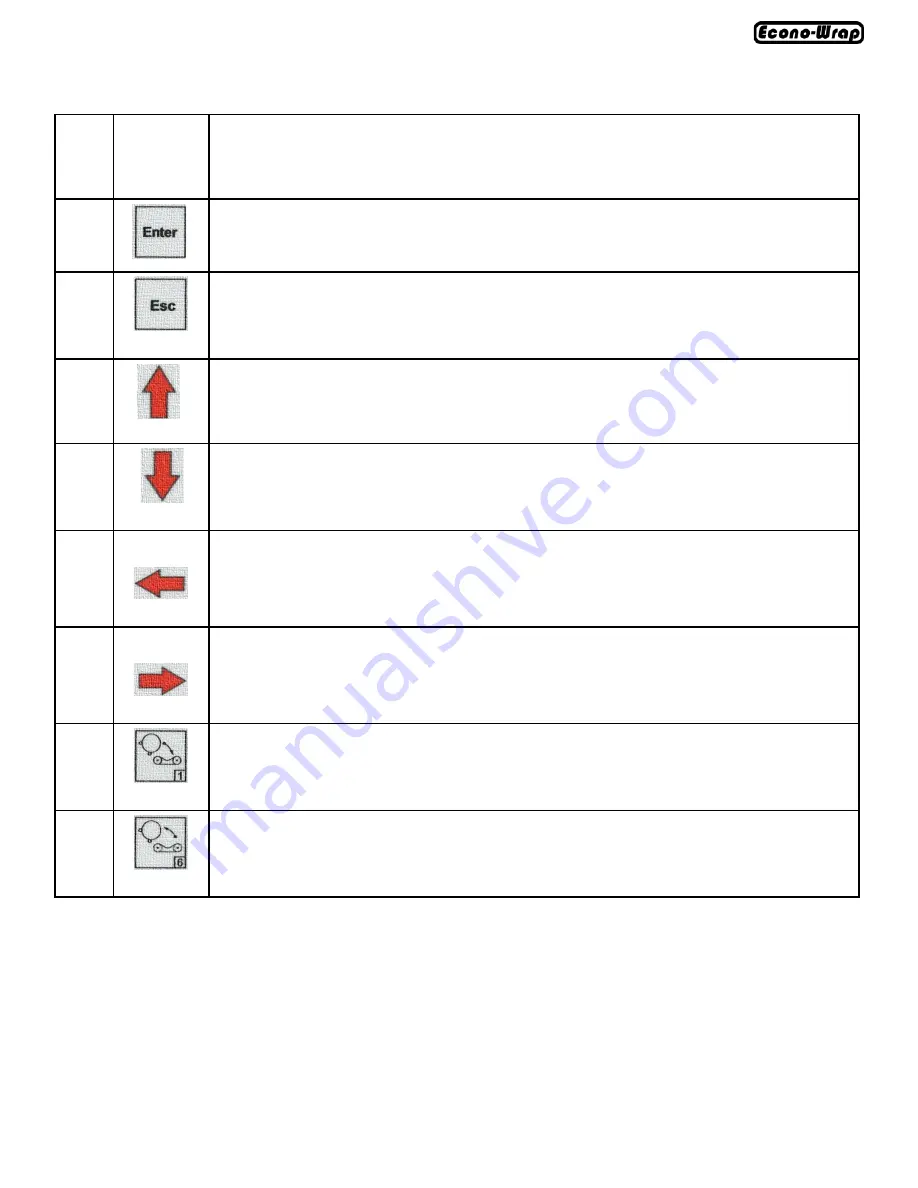

8.1.1 Description of functions of the control unit

NO.

KEY

DESCRIPTION

1

Confirms selection

2

Cancels selection and exits the selected screen

3

Moves cursor up

4

Moves cursor down

Inserts a dot

5

Moves cursor left

6

Moves cursor right

7

Raises the bale lift

Enters

“1”

8

Lowers the bale lift

Enters

“6”

Summary of Contents for EW-1800T

Page 1: ...Rel 06 07 21 Self loading Bale Wrapper EW 1800T Operator s Manual...

Page 2: ...Self loading Bale Wrapper EW 1800T 2 Page left blank intentionally...

Page 17: ...Self loading Bale Wrapper EW 1800T 17 Table 2 cont Safety decals on the machine...

Page 18: ...Self loading Bale Wrapper EW 1800T 18 Table 2 cont Safety decals on the machine...

Page 89: ...89 Rel 06 07 21 Self loading Bale Wrapper EW 1800T Parts Manual 89...

Page 90: ...Self loading Bale Wrapper EW 1800T 90 Page left blank intentionally...

Page 92: ...Self loading Bale Wrapper EW 1800T 92 12 2 Bottom frame set...

Page 106: ...Self loading Bale Wrapper EW 1800T 106 12 15 Rotary frame set...

Page 108: ...Self loading Bale Wrapper EW 1800T 108 12 16 Film cut and hold set...

Page 110: ...Self loading Bale Wrapper EW 1800T 110 12 17 Dispenser post set...

Page 122: ...Self loading Bale Wrapper EW 1800T 122 12 28 Hydraulic system...

Page 126: ...Self loading Bale Wrapper EW 1800T 126 Page left blank intentionally...

Page 127: ...Self loading Bale Wrapper EW 1800T 127 Page left blank intentionally...