This bale wrapper is suitable for use with tractors of a 0.9 minimum class and

with power more than 30 KW equipped with a set of weights on the front axle.

Its design is adapted for it’s connection with the Three Point Hitch of the tractor.

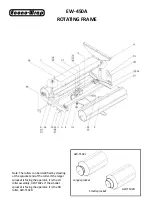

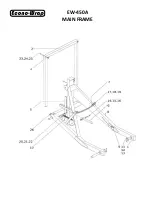

The Rotation frame shown as number 3 on the previous page placed on the lower frame shown as

number 2 is connected aligned with the main frame shown as number 1 and is suspended on the three-

point system of tractor. The lower frame together with the rotation frame is secured against deflection by a

movable locking pin. Unloading the bales from the bale wrapper is possible after unlocking the pin and after

the bale wrapper is raised using the Three Point Hitch of the tractor. It then unloads as the lower frame is

tilted and the frame is rotated thus unloading the bales

The movement of the rotation frame and the rotation drums shown as by the number 5 on the previous

page is carried out by the operation of the hydraulic motor, number 6 with overload valve wihich is operated

by the hydraulic pump of tractor. This overload valve provides for smooth starting and stopping of the

machine. It also protects the mechanical components of the drive from damage as a result of excessive

load. The valve is factory-tuned to the engine and sealed. It should not be adjusted unnecessarily..

The drive from the engine is transmitted via a 5/8” (10B) chain on the chain wheel of rotation frame.

This provides for a rotation of the bale along the vertical axis. Next, power is transmitted to the drums

welded via a conical toothed gear and two chain transmissions. This provides a rotation of the bale

with the appropriate ratio in the horizontal axis, this causes a partial overlapping film layers and

tightness of the layer. Roll of film is placed in the feeder (4). The film is stretched through the two tension

rolls connected with toothed gear, which ensures tight adhesion of subsequent layers of film.

The transmission ratio is chosen so as to ensure

the optimal stretching the film, however, if

necessary, stretching can be adjusted by

tightening the nut pressure of film. The maximum

extension/elongation of the film should not

exceed 70% of original length. That is, segment of

film with the length of 10 cm after stretching,

should not be longer than 17cm. should be applied a

polyester film, stretch film, self-adhesive with

stabilizer of ultraviolet rays with a thickness of 0.025-

0.03mm and the width of 500 or 750 mm.

Summary of Contents for EW-450A

Page 1: ...Operator s Manual Rev 05 22 Stationary Bale Wrapper EW 450A...

Page 13: ...Parts Breakdown...

Page 16: ...EW 450A LOWER FRAME...

Page 18: ...EW 450A MAIN FRAME...

Page 20: ...EW 450A FILM FEEDER...

Page 22: ......