Attempt/test of the operation

Before start wrapping, you should check the operation of the machine:

Raising on Three Point Hitch of tractor;

Smoothness and direction of rotation of rotating frame and drums (rotations of the frame - to the left /

counter clockwise);

Operation of the interlocking, tilting the lower frame and the state of the chain. A chain attached to the

brackets of main frame restricts/limits the size of the tilting while unloading the wrapped bale. After lowering

of bale wrapper and return of the lower frame to horizontal position, locking pin when extended secures

the frame before tilting;

At the start of the hydraulic system please take special care, one should check whether in the field of rotation

of rotational frame with drums there are no people or objects, starting the warning with sound signal;

During operation the wrapper, the pin must absolutely block lower frame before tilting;

Extension /elongation of film as a result of tension, must not be more than 70% i.e. the length of the

unstretched film of 10 cm should increase to not more as 17 cm and width for the film of 750 mm should

not be smaller than 600 mm and for film of 500, not smaller than 400 .

Attention!

Before starting the machine, please take particular care. Lower frame must be secured before

tilting with locking pin.

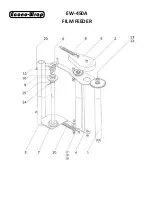

Installation of film

To install the film roll, one should tilt the bracket with rubber rollers.

After removing the clamping nut, install the roller so that was embedded on the lower clamping ring, then

secure from the top with clamping ring and the clamping nut. Clamp/press down the bracket with rubber

rollers, check whether they are properly pressed against film. In the event of non-parallelism on the contact

of film roller and rubber roller, one should adjust the position of the roll by overbending the fastening rod. In

accordance with the diagram, drag the film by rubber rollers so that it is possible to grasp the tip of the

film.

Fig.7

Diagram

of

installing

Film

Roll

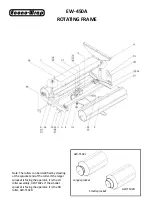

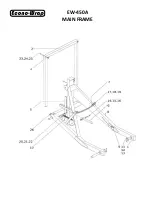

Summary of Contents for EW-450A

Page 1: ...Operator s Manual Rev 05 22 Stationary Bale Wrapper EW 450A...

Page 13: ...Parts Breakdown...

Page 16: ...EW 450A LOWER FRAME...

Page 18: ...EW 450A MAIN FRAME...

Page 20: ...EW 450A FILM FEEDER...

Page 22: ......