12

SAFETY

SYMBOLS

The

machine

is

marked

with

yellow

safety

symbols

with

a

descrip on.

The

meaning

and

placement

of

the

individual

sym

‐

bols

is

explained

below.

The

symbols

should

be

kept

clean

and

legible.

Lost

or

illegible

symbols

should

be

replaced

with

new

ones.

Symbols

can

be

purchased

from

the

manufacturer.

The

legibility

of

symbols

should

be

checked

on

a

regular

basis.

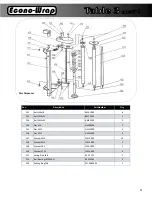

Fig.

1

Obligation to read the

instructions for use before

machine operation (on the

main frame)

Fig. 3

Direction and number of

frame rotations

(on the front cover)

Fig. 2

Pictogram

(on the main frame

)

12 rpm

The user is obliged to read the instruction manual

before starting the machine and comply with

occupational safety recommendations during its

operation.

Fig.

8

Pictogram

(on the main frame)

Fig.

9

Direction of rotations

(on the longitudinal cover)

Keep at least 4' away

from the working machine

12

Fig.

7

Turn off the engine and take out

the key before starting servicing

or repairs.

(on the main frame)

Fig.

5

Ban on exceeding the speed

limit

(on the back cover)

Fig.

6

Pictogram

(by the roller knife)

Caution -

sharp knives

Fig.

4

Diagram of the film route in the

dispenser

(on the film dispenser

)