PoolMaster

pro

™

Solar Pool Heating System -- Installation & User Manual

© Copyright 2020 Optex Solar Pty Ltd. All rights strictly reserved.

Page 27

16

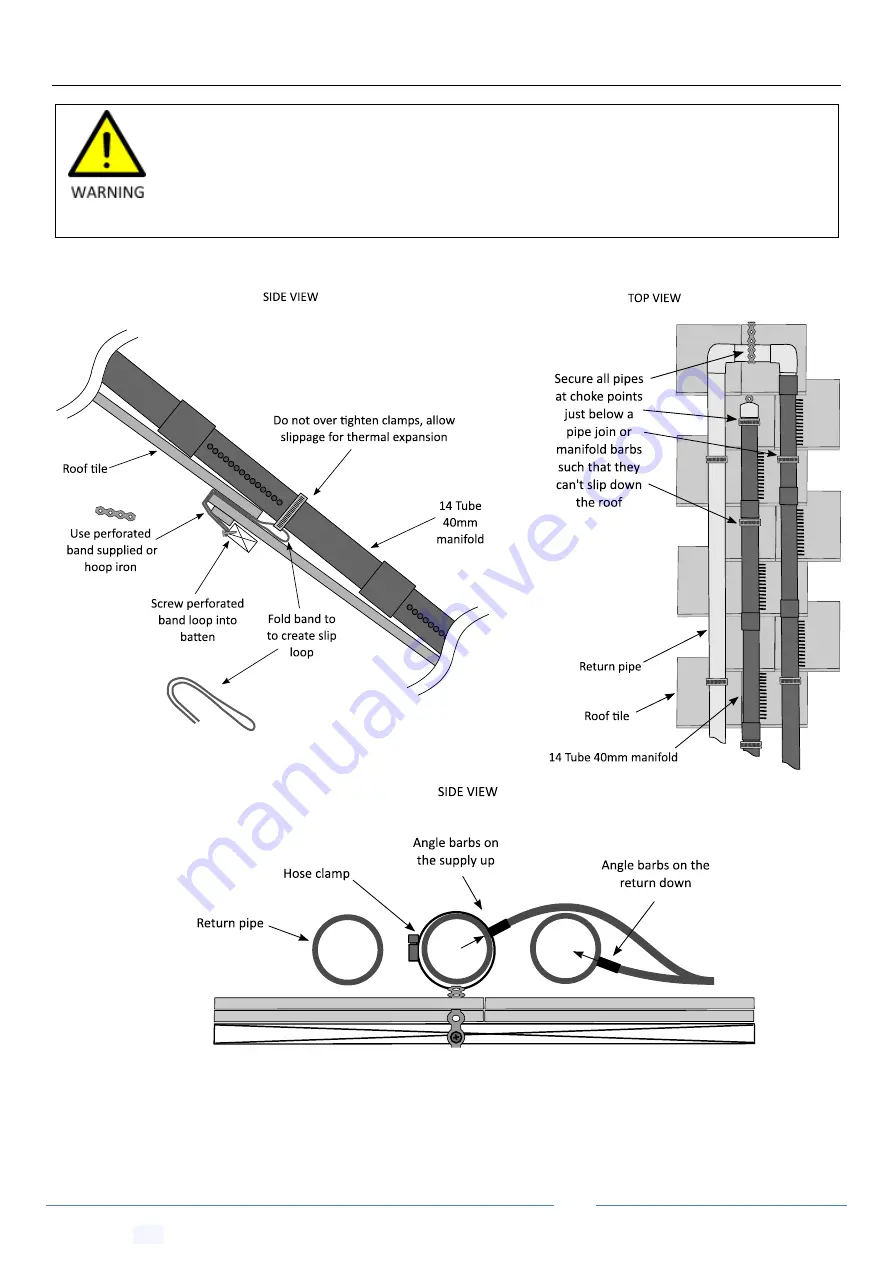

Roof Assembly and Attachment

16.1

Tile Roof Mounting of Manifold Assembly

When working with power or hand tools always follow the safety instructions. Wear the

recommended personal protective apparel. Make sure electrical cables are kept away from

any water and from foreign objects which pose

a potential cable severing or crushing hazard

.

When using glues, solvents or sealing agents make sure

you know and seek the proper first

aid

in case of an accident.