21

Troubleshooting

Need help troubleshooting? Call Toll Free 1-800-693-1138

or visit

www.ecopure.com

When you call, please be prepared to provide the model and serial number,

found on the rating decal, located on the rim below the salt lid hinges.

RESETTING TO FACTORY DEFAULTS

To reset the electronic controller to its factory default

for all settings (time, hardness, etc.):

1.

Press the SELECT button and hold it until the dis-

play changes twice to show “SET CODE” and the

flashing model code.

2.

Press the

p

UP button (a few times, if necessary)

to display a flashing “SoS”.

3.

Press the SELECT button, and the electronic con-

troller will restart.

4.

Set the present time, hardness, etc., as described

on pages 12 & 13.

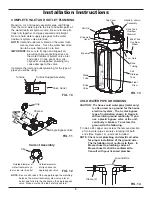

MANUAL ADVANCE REGENERATION

CHECK

This check verifies proper operation of the valve

motor, brine tank fill, brine draw, regeneration flow

rates, and other controller functions. Always make

the initial checks, and the manual initiated diagnos-

tics.

NOTE:

The electronic control display must show a

steady time (not flashing). If an error code

shows, first press the SELECT button to enter

the diagnostic display.

1

. Press the RECHARGE button and hold in for 3

seconds. RECHARGE begins to flash as the sys-

tem’s valve advances from the service to fill posi-

tion. Remove the brinewell cover and, using a

flashlight, observe fill water entering the tank.

If water does not enter the tank, look for an

obstructed nozzle, venturi, fill flow plug, brine tub-

ing, or brine valve riser pipe.

2

. After observing fill, press the RECHARGE button to

move the system’s valve into the brine position. A

slow flow of water to the drain will begin. Verify

brine draw from the brine tank by shining a flash-

light into the brinewell and observing a noticeable

drop in the liquid level. This may take 15 to 20

minutes.

NOTE:

Be sure water is in contact with the salt, and

not separated by a salt bridge (See "Breaking

A Salt Bridge" section).

If the water treatment system does not draw brine,

check for (most likely to least likely):

=

Dirty or plugged nozzle and venturi, see

"Cleaning the Nozzle and Venturi" section.

=

Nozzle and venturi not seated on the gasket, or

gasket deformed.

=

Valve seals leaking.

=

Restriction in valve drain, causing a back-pres-

sure (bends, kinks, elevated too high, etc.). See

"Install Valve Drain Hose" section.

=

Obstruction in brine valve or brine tubing.

NOTE:

If water system pressure is low, an elevated

drain hose may cause back pressure, stop-

ping brine draw.

3

. Press the RECHARGE button to move the sys-

tem’s valve into the backwash position. Look for a

fast flow of water from the drain hose. Check that

the drain can adequately handle the flow and vol-

ume.

An obstructed flow indicates a plugged top distribu-

tor, backwash flow plug, or drain hose.

4

. Press the RECHARGE button to move the sys-

tem’s valve into the fast rinse position. Again look

for a fast drain flow. Allow the water treatment sys-

tem to rinse for a few minutes to flush out any

brine that may remain in the resin tank from the

brining cycle test.

5

. To return the system’s valve to the service position,

press the RECHARGE button.

FIG. 40