Air-Cooled Direct-Expansion and Air-Cooled DualCool Units Only

Ecosaire

®

EN Series Precision Air Conditioner Owners Manual

32

Ecosaire

®

July 2009

Data subject to change without notice.

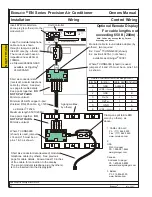

Installation Piping Refrigerant-Tube Joining

After eliminating all leaks, locate the refrigerant receiver in the remote condenser

unit. Open the receiver isolation valves (if any).

evacuation manifold

(by others)

hoses

(by others)

vacuum pump with

isolation valve

(by others)

refrigeration manifold

(by others)

refrigerant

and scale

(by others)

essential electronic

evacuation gauge

(by others)

liquid-line access

valve added

previously

(by others)

Open the compressor(s) rotalock valves to the access (middle) position. The

Ecosaire® unit, condenser, and tubes must be evacuated to a pressure below 500

microns of mercury as measured by an electronic vacuum gauge.

Compound gauges

as found on refrigeration manifolds are not adequate.

IMPORTANT!

Under no circumstances use the compressor as a vacuum pump or apply power to a compressor under

vacuum. Damage to the motor windings will result.

Connect a good set of refrigeration service gauges, an electronic micron-level vacuum gauge, and a vacuum pump

as shown below. Use core-removal adapters to remove the cores from Schraeder-type access valves.

To insure a correct vacuum reading, install the electronic vacuum gauge far away from the vacuum pump

or use a reliable vacuum valve to isolate the gauge and system from the pump while reading the vacuum.

Colder ambient temperatures require longer evacuation times. Allow enough time at low pressures to remove any

water from the tubes. The triple-evacuation method can be helpful.

After proper evacuation, close the vacuum pump valve and break the vacuum with vapor refrigerant until a positive

pressure is reached.

Close the compressor rotalock valves.

Continue adding the specified weight and type of refrigerant (by others), through the condenser

access valve, until the total amount shown in BOX A has been added.

Add the amount and type of oil shown in BOX B and BOX C.

Replace the access-valve cores and remove the adapters.

DO NOT put liquid refrigerant into the low-pressure access valve.

Open compressor

rotalock valves to access

position during evacuation.

INST

ALLA

TION

EXAMPLE

Appearance, location, and

quantity of component

s

may vary

.

BOX A

BOX B

BOX C

Summary of Contents for EN Series

Page 1: ......

Page 103: ...OEM User manual ...

Page 104: ......

Page 106: ......

Page 108: ......

Page 110: ......

Page 123: ...OEM CAREL code 030221791 rel 2 1 21 09 07 15 4 2 Single phase wiring diagram INTERNAL TAM CP2 ...

Page 141: ......