36

Ecosaire

®

July 2009

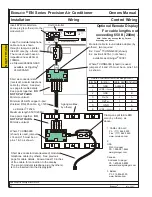

After all piping connections have

been completed, the system should

be leak tested by pressurizing it with

air to approximately 50 psig. Check

each joint with soap solution or per-

form a pressure-drop vs. time test.

After testing, the system can be

charged with the glycol/water mix-

ture.

First, determine the proper water-

to-glycol mixture to provide adequate

freeze protection in your area. This

may already have been determined

by a consulting engineer. Do not

exceed the recommended glycol

concentration for your area since

increased concentrations reduce

heat exchange efficiency. These

concentrations and corresponding

freeze temperatures are listed in the

table included here.

IMPORTANT!

Use only an inhibited ethylene

glycol suitable for HVAC

applications, such as Dowtherm

SR-1 or equivalent. DO NOT use

automotive antifreeze since it may

damage components.

All glycol-cooled and FreeCool

data is based on forty-percent

glycol by volume.

If possible use a pre-mixed gly-

col/water solution. Where this is not

possible, mix the solution by

volume in a clean non-galvanized

container.

Open the fill valve and all air vents,

including the petcocks at the top of

the

FreeCool coils

on the right-

hand side of the unit.

The pipe plugs on the pump impeller

housing and at the top of the room

unit inlet and outlet headers should

be carefully loosened to permit air to

escape.

Do not remove the plugs since they

can be difficult to replace once glycol

reaches the port. The core of the

access valve on the glycol-cooler

inlet header must be held open or

temporarily removed.

Pour the glycol mixture into the

system fill port until full.

E

cosaire

®

EN Series Precision Air Conditioner Owners Manual

Data subject to change without notice.

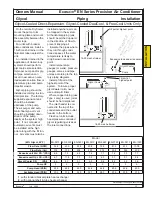

0

10

20

30

40

50

32

25

16

4

-11

-33

9.0

4.0

2.3

1.5

1.0

GLYCOL SOLUTIONS

Percent

Ethylene

Glycol

Solution

Freezing

Point (°F)

Gallons of Water

Per Each Gallon

of Ethylene Glycol

All Water

Glycol-Cooled

Model No.

Brazed-Plate Cond.

Shell & Tube Cond.

EN-027G

EN-035G

EN-042G

EN-051G

EN-068G EN-079G

EN-087G

EN-102G

INTERNAL VOLUMES (GALLONS)

Installation Piping Glycol Filling

Glycol-Cooled Direct-Expansion, Glycol-Cooled DualCool, & FreeCool Units Only

INST

ALLA

TION

GVD122F-F14

5.8

Glycol Cooler

Model @ 95°F

Internal Volume

GVD123F-F21

8.8

GVD124E-F29

11.7

GVD133D-F43

12.9

GVD133E-E26

15.6

GVD134C-F29

17.2

GVD143E-F43

17.1

GVD224E-F58

23.3

0.3

1.2

0.3

1.2

0.4

1.6

0.4

1.6

0.4

1.6

0.4

1.6

0.7

2.2

0.9

3.6

FreeCool

Model No.

Brazed-Plate Cond.

Shell & Tube Cond.

EN-027F

EN-035F

EN-042F

EN-051F

EN-068F

EN-079F

EN-087F

EN-102F

INTERNAL VOLUMES (GALLONS)

GVD122F-F14

5.8

Glycol Cooler

Model @ 95°F

Internal Volume

GVD123F-F21

8.8

GVD124E-F29

11.7

GVD133D-F43

12.9

GVD133E-E26

15.6

GVD134C-F29

17.2

GVD143E-F43

17.1

GVD224E-F58

23.3

5.5

6.4

7.0

7.9

7.1

8.3

7.1

8.3

10.7

11.9

10.7

11.9

11.0

12.5

11.2

13.9

Summary of Contents for EN Series

Page 1: ......

Page 103: ...OEM User manual ...

Page 104: ......

Page 106: ......

Page 108: ......

Page 110: ......

Page 123: ...OEM CAREL code 030221791 rel 2 1 21 09 07 15 4 2 Single phase wiring diagram INTERNAL TAM CP2 ...

Page 141: ......