Ecosaire

®

EN Series Precision Air Conditioner Owners Manual

38

Ecosaire

®

July 2009

Data subject to change without notice.

J

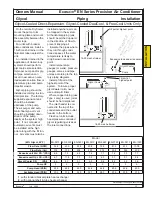

Installation Wiring Power

IMPORTANT!

Before working on this or any

electrical equipment, disconnect

all electrical power. Failure to

do so may result in serious per-

sonal injury or death due to

accidental electrical shock.

The branch-circuit conductors

should be brought through the unit

cabinet to the high-voltage terminal

strip or factory-mounted disconnect

switch.

Wiring for the unit and remote

heat exchanger (if any) should

comply with applicable codes.

Important!

Always cover the electrical

components with plastic sheet

before drilling or sawing the

electrical enclosure. Do not

allow metal chips to fall into the

enclosure.

Important!

Use only copper conductors to

connect the unit. The power

input lugs are not sized for use

with other conductors. THE USE

OF OTHER THAN COPPER CON-

DUCTORS WILL VOID THE

EQUIPMENT WARRANTY. For

units with factory-supplied dis-

connects, follow instructions

inside the disconnect.

Important!

Ground the unit using the

grounding lug provided.

Important!

For

••

Air-Cooled Direct Expansion,

••

Glycol-Cooled Direct-

Expansion,

••

Air-Cooled DualCool,

••

Glycol-Cooled DualCool, and

••

FreeCool units

refer to the remote heat-

exchanger manual.

Wire the remote heat

exchanger according to the

wiring diagram provided with it.

Insure that the fan motors turn

in the correct direction.

Use properly sized wire

Refer to the unit nameplate for

electrical ratings. Size wires

according to applicable codes, with

allowance for voltage drops. Unit

terminal voltage should be nominal

±10% under all conditions, includ-

ing compressor starting.

Insure phase rotation

All the motors in the unit are con-

nected for the same phase rota-

tion. Be sure the phase rotation is

correct before completing the

installation.

Do not move any

factory-installed wires.

NOTE: The blower running direc-

tion can be used to test phase

rotation.

Insure phase voltage

The

Ecosaire

® unit complies with

NEMA MG-1 and other standards

for applied voltage. The applied

voltage should be within ±10% of

the nominal voltage shown on the

nameplate. See ANSI C84.1.

Phase voltages should be bal-

anced within 2%.

208V units

A minimum of 187V at the com-

pressor terminals is required for

compressor starting (see NEMA

MG-1). Allow for voltage drop

under inrush current conditions.

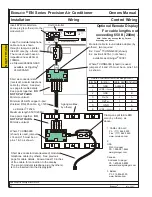

Connect input power as indicated.

Use copper wire only. Torque all connectors per NEC 110-14 or relevant code.

Position of power lugs may vary.

Some

Ecosaire

®

units may have optional

voltage monitors that prevent operation in the

event the branch circuit has voltage that is too

high, too low, has lost a phase, or has reversed

phase rotation. If the green LED

is not lit when power is applied to the unit, con-

firm that the applied voltage is within ±10% of

the nameplate voltage (NEMA MG-1), that all

three phases are present, and that the phase

rotation is correct.

INST

ALLA

TION

EXAMPLE

Appearance, location, and

quantity of component

s

may vary

.

Summary of Contents for EN Series

Page 1: ......

Page 103: ...OEM User manual ...

Page 104: ......

Page 106: ......

Page 108: ......

Page 110: ......

Page 123: ...OEM CAREL code 030221791 rel 2 1 21 09 07 15 4 2 Single phase wiring diagram INTERNAL TAM CP2 ...

Page 141: ......