Owners Manual Ecosaire

®

EN Series Precision Air Conditioner

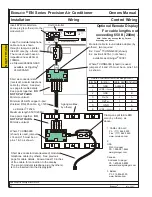

Check Valve Positions Pre-Startup Adjustments Startup

Ecosaire

®

July 2009

51

Data subject to change without notice.

For

Glycol-Cooled DualCool units and FreeCool

units, be

sure that any fluid valves (by others) are open.

For

Water-Cooled Direct-Expansion

units, be sure any

water valves (by others) are open.

For

Glycol-Cooled Direct-Expansion

units, be sure any glycol valves (by others)

are open.

ST

ARTUP

Ecosaire

Ecosaire

Ecosaire

EXAMPLES

Appearance, location, and

quantity of component

s

may vary

.

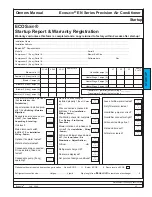

Summary of Contents for EN Series

Page 1: ......

Page 103: ...OEM User manual ...

Page 104: ......

Page 106: ......

Page 108: ......

Page 110: ......

Page 123: ...OEM CAREL code 030221791 rel 2 1 21 09 07 15 4 2 Single phase wiring diagram INTERNAL TAM CP2 ...

Page 141: ......