09.06.2017 Rev. 08

43

Combustion Adjustment

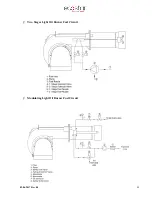

Ø

Fuel nozzle

Use proper wrench in installation and dismantle of the fuel

nozzle.

Use diesel oil to clean the fuel nozzle. Do not use thinner

and its derivatives.

Ø

Photocell

Check the photocell weekly. Clean the dust or fume stains on the glass of

photocell by a dry cloth.

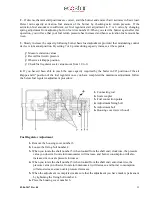

Fuel Pumps

E Type

1- Suction or vacuum manometer connection

2- Return and internal bypass

3- Nozzle outlet

4- Manometer connection

5- Vacuum manometer connection

6- Pressure adjustment

Summary of Contents for ECO 50 K L C 2

Page 10: ...09 06 2017 Rev 08 9 Burner Components ECO 50 KLC2...

Page 12: ...09 06 2017 Rev 08 11 ECO 55 KLC2 2a...

Page 14: ...09 06 2017 Rev 08 13 ECO 60 KLC2...

Page 16: ...09 06 2017 Rev 08 15 ECO 65 KLC2...

Page 18: ...09 06 2017 Rev 08 17 ECO 70 KLC2...

Page 20: ...09 06 2017 Rev 08 19 ECO 50 KLC3...

Page 22: ...09 06 2017 Rev 08 21 ECO 55 KLC3 3a...

Page 24: ...09 06 2017 Rev 08 23 ECO 60 KLC3...

Page 26: ...09 06 2017 Rev 08 25 ECO 65 KLC3...

Page 28: ...09 06 2017 Rev 08 27 ECO 70 KLC3...

Page 30: ...09 06 2017 Rev 08 29 ECO 75 KLC3...

Page 33: ...09 06 2017 Rev 08 32 Back Pressure Capacity Diagrams...

Page 34: ...09 06 2017 Rev 08 33 Burner Dimensions...

Page 36: ...09 06 2017 Rev 08 35...

Page 37: ...09 06 2017 Rev 08 36...

Page 49: ...09 06 2017 Rev 08 48 MB ZRD LE 405 412 Series Gas Valve...

Page 58: ...09 06 2017 Rev 08 57 Light Oil Burner Fuel Ring Line...