10

Step 3

:

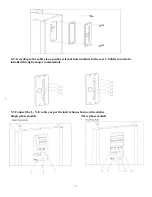

Tighten

3 screws in the 3 upper dowel pins, as shown in the

Figure

Step 4:

Mount the

heater

on 3 fixed screws. Tighten 2 screws in the lower dowel pins

5. Electrical connections

1. All electrical works shall be in conformity with the currently valid national and local electrical standards.

2. The heater shall be properly grounded via a dedicated grounding loop with a suitable voltage design.

3. Ensure that the ends of metal wires to the terminal strips/circuit breakers make full contact when laying the

cable to the terminal strips/circuit breakers. Then tighten the screws to ensure maximum current voltage.

4. Before commencement of electrical works, ensure that the switch of the main power board circuit breaker

is in the OFF position, to avoid any hazards due to electric shock; all installation and plumbing works shall be

performed prior to electrical connections.

5. Ensure a circuit breaker and a hole on the heater side for wiring.

5.1 Untighten the screws and then remove the hole cover.