17

ECOWATER

S Y S T E

M S

Service Information

REFILLING WITH SALT

Remove the brine tank cover and check the salt stor-

age level frequently. If the conditioner uses all the

salt before you add more, you will get hard water.

Be

sure the brinewell cover is on when adding salt.

NOTE:

In humid areas, it is best to keep the salt stor-

age level lower, and to refill more often.

RECOMMENDED SALT:

Cube, pellet, coarse so-

lar, etc., water conditioner salt is recommended.

This type of salt is from high purity evaporated crys-

tals, sometimes formed, or compressed, into bri-

quets. It has less than 1% insoluble (will not dissolve

in water) impurities.

Clean, high grade

rock salts are

acceptable, but may require frequent brine tank

cleaning to remove the ‘‘sludge’’ residue (insolu-

bles) that collects at the bottom of the tank.

SALT NOT RECOMMENDED:

Rock salt, high in im-

purities, block, granulated, table, ice melting, ice

cream making salts, etc., are not recommended.

SALT WITH IRON REMOVING ADDITIVES:

Some

salts have an additive to help a water conditioner

handle iron in a water supply. Although this additive

may help keep the resin bed clean, it may also re-

lease corrosive fumes that will weaken and shorten

the life of some EcoWater Systems conditioner

parts.

BREAKING A SALT BRIDGE

Sometimes, a hard crust or salt bridge forms in the

brine tank. It is usually caused by high humidity or

the wrong kind of salt. When the salt bridges, an

empty space forms between the water and the salt.

Then, salt will not dissolve in the water to make

brine. Without brine, the resin bed is not regener-

ated and you will have hard water.

If the brine tank is full of salt, it is hard to tell if you

have a salt bridge. Salt is loose on top, but the bridge

is under it. Take a broom handle, or like tool, and

push it straight down into the salt. If a hard object is

felt, it’s most likely a salt bridge.

Carefully

push into

the bridge in several places to break it.

RESIN BED CLEANING

If the water supply contains ‘‘clear water ’’ iron (see

page NO TAG), regular resin bed cleaning is need-

ed to keep the bed from coating with iron. Use resin

bed cleaner, available from EcoWater Systems, fol-

lowing directions on the container. Clean the resin

every 6 months, or more often if iron appears in your

conditioned water supply.

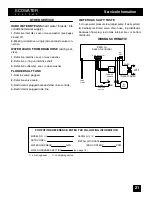

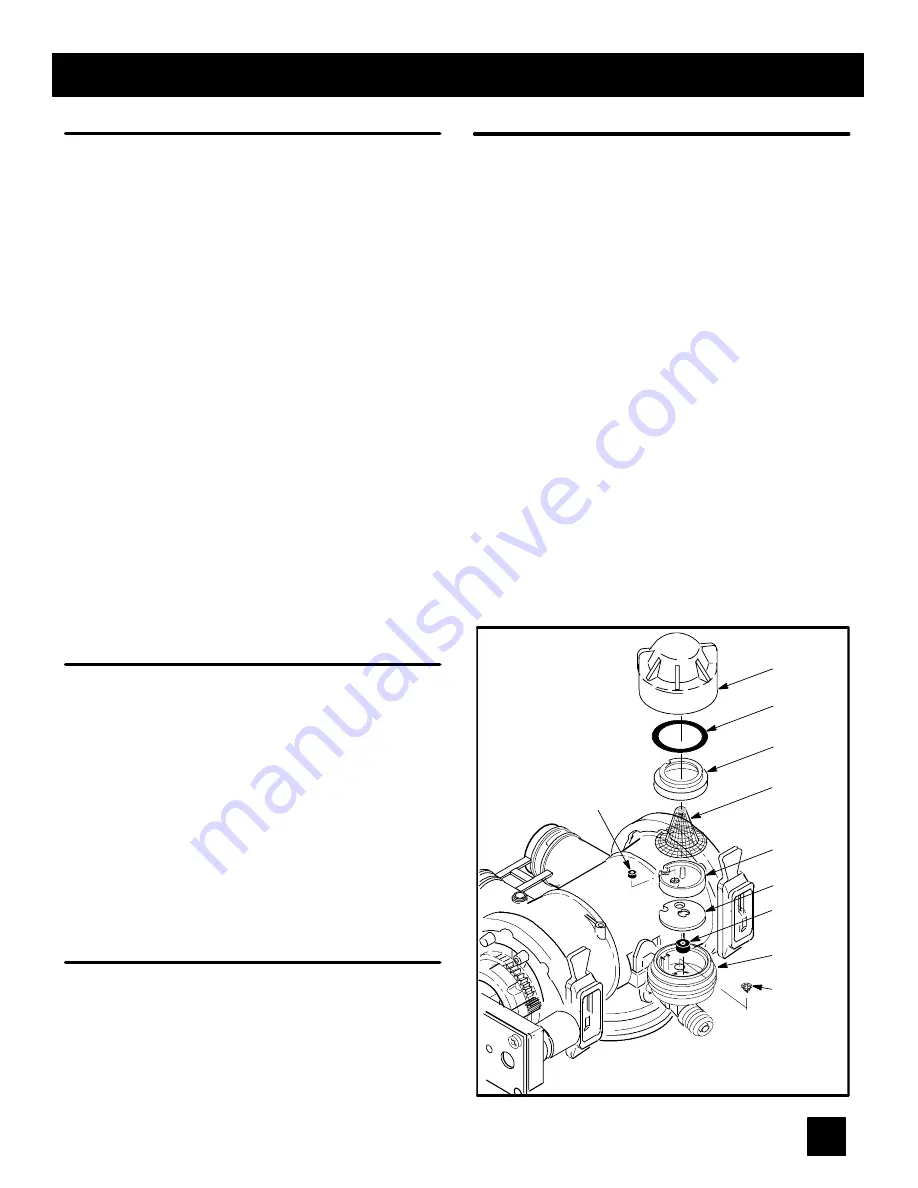

CLEANING THE NOZZLE AND VENTURI

A clean nozzle and venturi (FIGURE 7) is a must for

the EcoWater Systems conditioner to work right.

This small unit creates the suction to move brine

from the brine tank, into the resin tank. If it should be-

come plugged with sand, silt, dirt, etc., the EcoWater

Systems conditioner will not work, and you will get

hard water.

To get to the nozzle and venturi, remove the condi-

tioner top cover.

Be sure the conditioner is in the

service cycle

(no water pressure at nozzle and

venturi). Then, holding the nozzle and venturi hous-

ing with one hand, turn off the cap.

Do not lose the

o--ring seal.

Lift out the screen support and screen.

Then, remove the nozzle and venturi. Wash the

parts in warm, soapy water and rinse in fresh water.

If needed, use a small brush to remove iron or dirt.

Be careful not to scratch, misshape, etc., surfaces

of the nozzle and venturi. Also, check and clean the

gasket and flow plug(s) if dirty.

Carefully replace all parts in the correct order. Lubri-

cate the o--ring seal with silicone grease and locate

in position. Install and tighten the cap,

by hand only.

Do not overtighten

and break the cap or housing.

cap

o--ring

screen

support

screen

nozzle &

venturi

gasket

flow plug

(fill)

nozzle &

venturi housing

cone

screen

flow plug

(not used

on all models)

install with

numbered

side UP

,

concave side

down

FIGURE 7