43

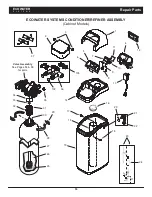

CLEANING THE NOZZLE & VENTURI

A clean nozzle & venturi (See Figure 154) is necessary

for the EcoWater Systems conditioner/refiner to work

properly. This small unit creates the suction to move

brine from the brine tank into the resin tank. If it should

become plugged with dirt, silt, sand, etc., the EcoWater

Systems conditioner/refiner will not work and hard water

will result.

To get access to the nozzle & venturi, remove the con-

ditioner/refiner’s top cover. Put the bypass valve(s) into

the bypass position. Be sure the conditioner/refiner is

in the service cycle (no water pressure at the nozzle &

venturi). Then, holding the nozzle & venturi housing

with one hand, turn the cap to remove it. Do not lose

the o-ring seal. Lift out the screen support and screen.

Then, remove the nozzle & venturi. Wash the parts in

warm, soapy water and rinse in fresh water. If needed,

use a small brush to remove iron or dirt. Be careful not

to scratch, misshape, etc., surfaces of the nozzle &

venturi. Also, check and clean the gasket and flow

plug(s) if dirty.

Carefully replace all parts in the correct order.

Lubricate the o-ring seal with silicone grease and put in

place. Install and tighten the cap, by hand only. Do not

overtighten, which could break the cap or housing. Put

the bypass valve(s) into service (conditioned water)

position.

cap

o--ring

screen

support

screen

nozzle &

venturi

gasket

flow plug

(fill)

nozzle &

venturi housing

cone

screen

flow plug

(not used

on all models)

install with

numbered

side UP

,

concave side

down

FIG. 154

RESIN BED CLEANING

If the water supply contains clear water iron, regular

resin bed cleaning is needed to keep the bed from coat-

ing with iron. Use resin bed cleaner, available from

EcoWater Systems, following directions on the contain-

er. Clean the resin every six months, or more often if

iron appears in the conditioned water supply.

ECOWATER

S Y S T E M S

Service Information