46

AUTOMATIC ELECTRONIC DIAGNOSTICS

This conditioner/refiner has a self-diagnostic function for

the electrical system (except for input power and/or

water meter). The controller monitors electronic com-

ponents and circuits for correct operation. If a malfunc-

tion occurs, an

Error code

is displayed (See Figure

157).

Error detected

Error code: 1

FIG. 157

The troubleshooting chart on the previous page shows

the error codes that could appear, and the possible mal-

functions for these codes.

When an error code appears in the display, pressing

SELECT (

¡

) will display the

Diagnostics

screen (See

Page 41), so a service technician can further isolate the

problem.

REMOVING ERROR CODE

1

. Unplug power supply from electrical outlet.

2

. Correct problem.

3

. Plug power supply back in.

4

. Wait for eight minutes while controller operates valve

through an entire cycle. The error code will return if

the problem was not corrected.

TROUBLESHOOTING -

MANUAL DIAGNOSTICS

1

. Display the

Diagnostics

screen, following the proce-

dure on Page 41.

2

. Press the DOWN (

6

) or UP (

5

) buttons to scroll

through the list. The following items are displayed:

=

Time

(current)

=

Position time

(counts down the time remaining

in the current valve position)

=

Current position

(of the valve: service, fill,

brine, backwash, fast rinse or moving) See

“Manual Advance Recharge Check” on next

page for position verification.

=

Requested position

(of the valve)

=

Motor state

(on or off)

=

Valve position switch

(open or closed)

=

Turbine count

(indicates water flow) See fol-

lowing section for turbine diagnostics.

=

Salt level sensor

(distance reading of sensor)

=

Drain TDS

(total dissolved solids in ppm)

=

Drain temperature

(°C)

=

Tank light switch

(open or closed)

=

RF module

(detected or not)

=

Error code

Diagnostics

Turbine count:

0

Salt level sensor:

456

FIG. 158

3

. A steady display of “0” (zero) indicates no water flow

through the meter (i.e. no conditioned water being

used).

4

. Open a nearby conditioned water faucet.

5

. The number in the display should count upward from

0 and reset at 151 for each gallon of flow.

6

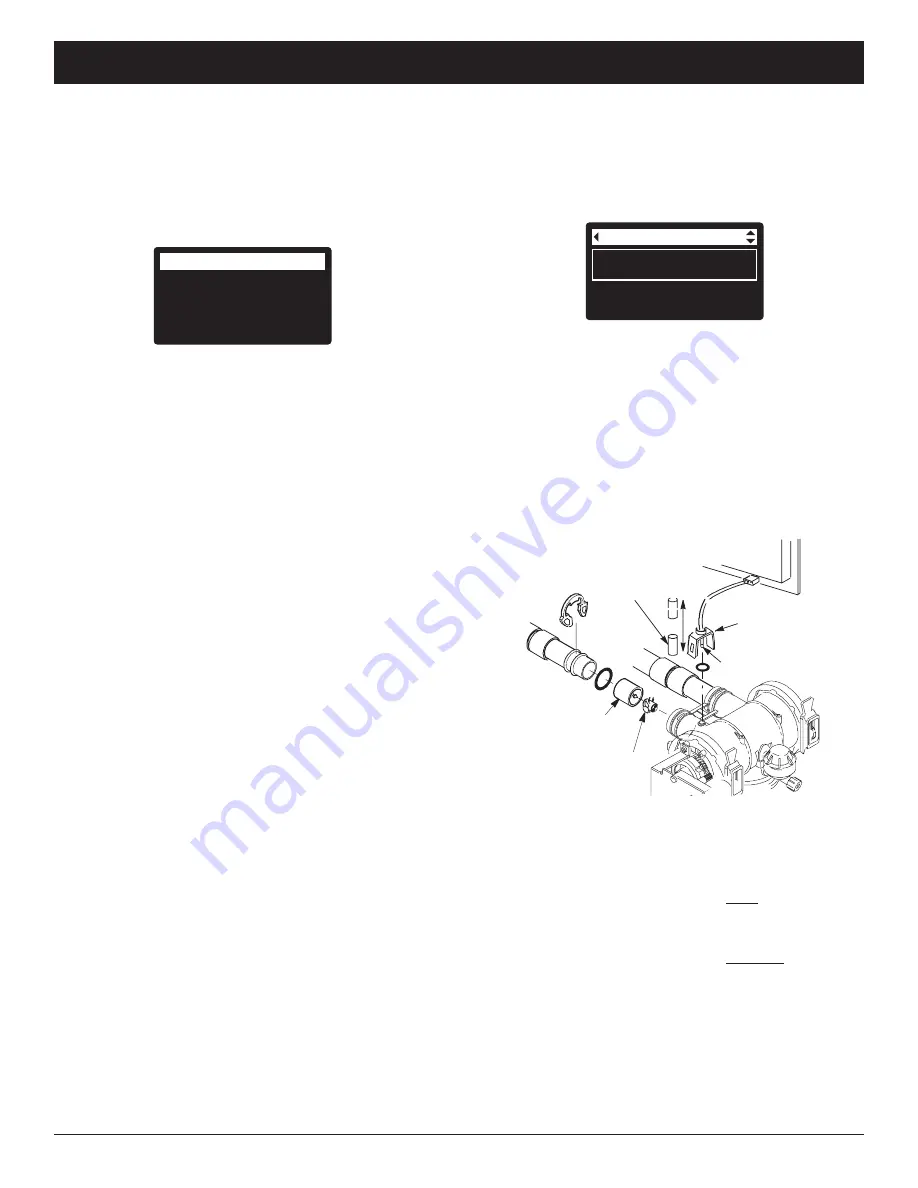

. If the display reading does not change with the

faucet open, pull the wire harness from the valve out-

let port (See Figure 159).

turbine

support

turbine

wire harness

BACK OF CONTROLLER

CIRCUIT BOARD

magnet

sensor pickup

FIG. 159

7

. Pass a small magnet back and forth in front of the

sensor.

8a

. If the displayed

Turbine Count

does count upward

with each pass of the magnet, disconnect the outlet

plumbing and check the turbine for binding.

8b

. If the displayed

Turbine Count

does not count

upward with each pass of the magnet, the sensor is

probably faulty.

CHECKING THE TURBINE

1

. Display the

Diagnostics

screen, following the proce-

dure on Page 41.

2

. Press the DOWN (

6

) button to scroll through the list

until

Turbine Count

is displayed (See Figure 158).

ECOWATER

S Y S T E M S

Service Information