7

ECOWATER

S Y S T E M S

Installation

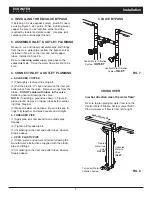

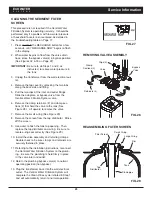

4. INSTALLING THREE-VALVE BYPASS

If installing a 3-valve bypass system, plumb as need-

ed using Figure 7 as a guide. When installing sweat

copper, be sure to use lead-free solder and flux,

required by federal and state codes. Use pipe joint

compound on outside pipe threads.

3 VALVE BYPASS

Central Water Filtration

System

INLET

Central Water Filtration

System

OUTLET

FIG. 7

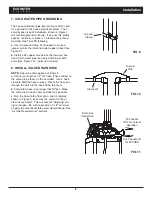

5. ASSEMBLE INLET & OUTLET PLUMBING

Measure, cut, and loosely assemble pipe and fittings

from the main water pipe (or from the bypass valves

installed in Step 4), to the inlet and outlet copper

tubes, installed in Step 2b.

Be sure

incoming water

supply pipe goes to the

valve inlet

side. Trace the water flow direction to be

sure.

6. CONNECT INLET & OUTLET PLUMBING

a. SOLDERED COPPER

(1) Thoroughly clean and flux all joints.

(2) Pull the plastic “C'' clips and remove the inlet and

outlet tubes from the valve. Remove o-rings from the

tubes.

DO NOT solder with tubes in the valve.

Soldering heat will damage the valve.

NOTE:

If installing a ground as shown in Figure 9,

place ground clamps on copper tubes before solder-

ing (See Step 6a).

(3) Make all solder connections. Be sure to keep fit-

tings fully together, and pipes square and straight.

b. THREADED PIPE

(1) Apply pipe joint compound to all outside pipe

threads.

(2) Tighten all threaded joints.

(3) If soldering to the inlet and outlet tubes, observe

Step 6a above.

c. CPVC PLASTIC PIPE

(1) Clean, prime and cement all joints, following the

manufacturer's instructions supplied with the plastic

pipe and fittings.

(2) If soldering to the inlet and outlet tubes, observe

Step 6a above.

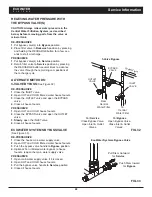

CROSS OVER

To Central Water

Filtration System

Main W

ater Pipe

In what direction does the water flow?

Be sure to plan piping so water flow is to the

Central Water Filtration System valve INLET.

Plan a crossover if flow is from left to right.

Treated

Water from

Valve

OUTLET

Untreated

Water to

Valve

INLET

FIG. 8