9

ECOWATER

S Y S T E M S

Installation & Sanitizing

9. PRESSURE TESTING FOR LEAKS,

PROGRAMMING THE CONTROLLER &

RINSING THE MEDIA

To prevent excessive air pressure in the water

softener and plumbing system, do the following

steps EXACTLY in order:

a

. Fully open two or more

softened

cold water

faucets nearby the water softener.

b

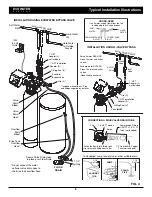

. Place the bypass valve(s) in

bypass

position (See

Figures 2 & 4).

c

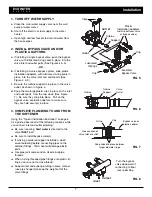

. Fully open the main water supply valve. Watch

until the flow from the opened faucets becomes

steady, with no spurting or air bubbles.

d

. After about three minutes, open a hot water faucet

for one minute, or until all air is expelled.

e

. Close all faucets and check your plumbing work for

leaks.

f

. Make sure the softener’s valve drain hose is

hooked up and the open end directed to a floor

drain, laundry tub or other suitable type of drain.

g

. Make sure the softener’s bypass valve is in the

bypass

position.

h

. Plug in the power supply.

i

.

Program the electronic controller:

Follow the

steps on Pages 10 and 11 to program the electronic

controller with basic operating information, such as

time and water hardness. After completing these

steps, continue with “j. Start a recharge”, below.

j

.

Start a recharge:

Press the RECHARGE button

and hold for 3 seconds, until “Recharge Now” flash-

es in the display and you hear the valve motor run

as the softener begins recharging.

k

. Once the unit is in backwash, place bypass

valve(s) into the

service

position, as follows:

(1) SINGLE BYPASS VALVE:

Slowly

move the

valve stem toward

service

position, pausing sev-

eral times to allow the unit to pressurize slowly.

(2) 3-VALVE BYPASS: Fully close the

bypass

valve and open the

outlet

valve.

Slowly

open

the

inlet

valve, pausing several times to allow the

unit to pressurize slowly.

l

. Let the softener complete the backwash and fast

rinse cycles (takes 10-12 minutes). When the

recharge cycle ends, the softener valve returns to

the service position.

10. ADD WATER AND SALT TO THE

BRINE TANK

a

. Using a pail or garden hose, add about 3 gallons of

water into the brine tank. DO NOT pour into the

brinewell.

b

. Add salt to the brine tank. It is recommended to fill

the brine tank no more than 1/2 full. Level the salt

when finished adding. You can use most water

softener salts, but it must be clean.

Recommended nugget, pellet or coarse solar salts

have less than 1% impurities.

NOTE:

See page 14 for additional information on salt.

11. SANITIZING THE WATER SOFTENER

Care is taken at the factory to keep your EcoWater

Systems water softener clean and sanitary. However,

during shipping, storage, installing and operating,

bacteria could get into the unit. For this reason, sani-

tizing as follows is suggested* when installing.

a

. Remove the brinewell cover and pour about 1-1/2

oz. (2 to 3 tablespoons) of common household

bleach into the softener’s brinewell. Replace the

brinewell cover.

b

. Make sure the bypass valve is in the

service

posi-

tion.

c

.

Start a recharge:

Press the RECHARGE button

and hold for 3 seconds, until “Recharge Now”

flashes in the display and you hear the valve motor

run as the softener begins recharging. This

recharge draws the sanitizing bleach into and

through the softener. Any air remaining in the unit

is purged to the drain.

d

. After the recharge has completed, fully open a cold

water faucet, downstream from the softener, and

allow 50 gallons of water to pass through the sys-

tem. This should take at least 20 minutes. Close

the faucet.

12. RESTART THE WATER HEATER

Turn on the electric or fuel supply to the water heater,

and light the pilot, if applies.

NOTE:

The water heater is filled with hard water and,

as hot water is used, it refills with softened water. In

a few days, the hot water will be fully conditioned. To

have fully conditioned hot water immediately, wait

until the recharge (Step 11) is complete, then drain

the water heater until water runs cold.

*

Recommended by the Water Quality Association. On

some water supplies, the EcoWater Systems unit may need

periodic disinfecting.