22

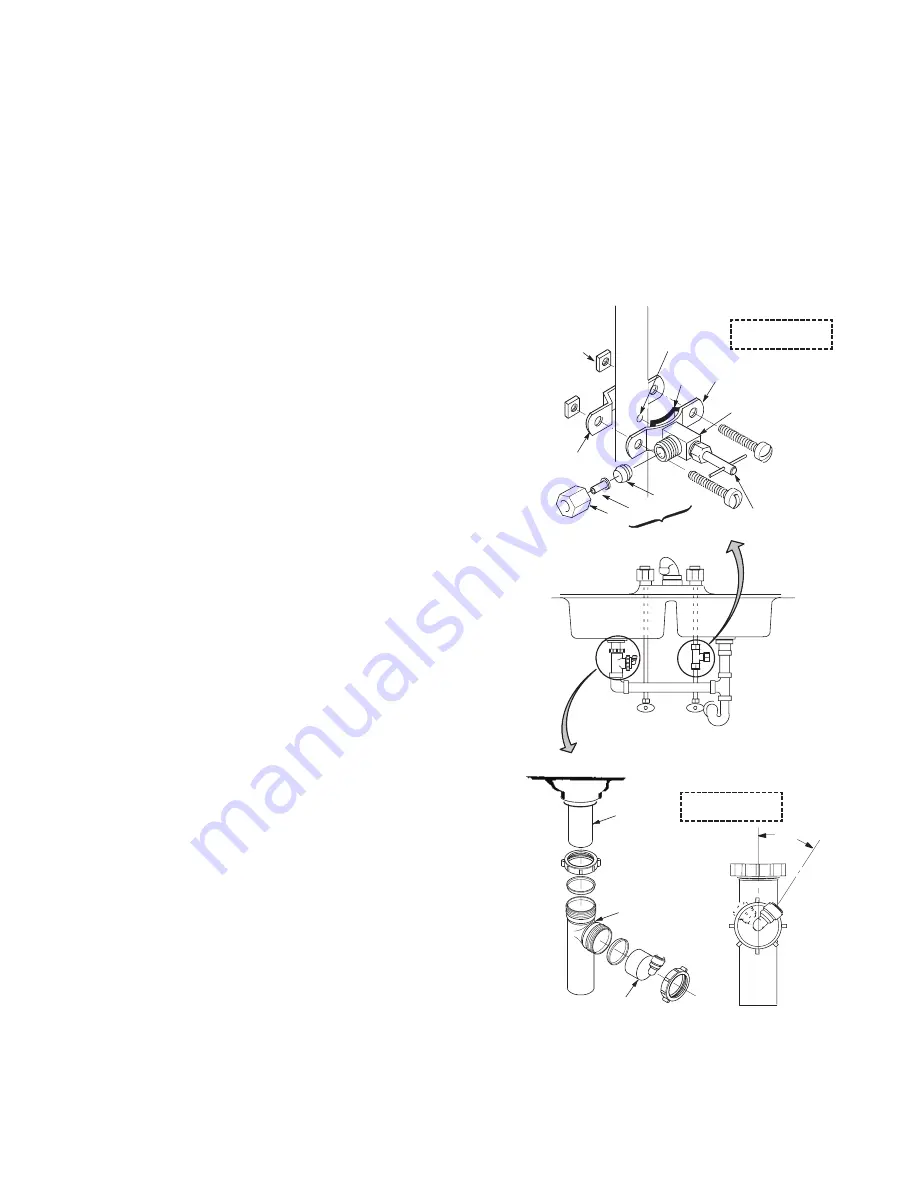

INSTALLATION OF OPTIONAL FITTINGS (not included)

SADDLE VALVE, not available from EcoWater

NOTE:

This type of valve pierces a hole in copper tub-

ing or plastic pipe. If installing on iron pipe, you have to

drill a 1/8" pilot hole for the piercing pin. Be sure to turn

off water to the pipe and to drain water from it before

drilling. READ THE FOLLOWING DANGER NOTE.

DANGER (IF DRILLING METAL PIPE):

To protect

yourself from serious injury or fatal shock, use a battery

powered hand drill only to make the hole. Do not use an

electric drill.

1.

Looking at Figure 21, turn the valve into clamp X

and tighten (may be preassembled). Turn the valve han-

dle all the way out.

2.

Place the seal on the inside of clamp X as shown. Be

sure the piercing pin does not stick out beyond the seal.

3.

Place clamp X and Z around the pipe and secure in

place with two screws. Tighten both screws evenly, but

do not overtighten. Clamp Z will either have threaded

screw holes, or two nuts are included.

4.

Carefully turn the handle inward to pierce a hole in

the copper or plastic pipe.

DRAIN ADAPTER, part no. 7192230

¢

The optional drain adapter installs in the sink drain

pipe, always above or ahead of the p-trap. Be sure to

comply with your local plumbing codes. Other drain pipe

fittings, in addition to the adapter, may be needed.

¢

The drain adapter fits 1-1/2" sink drain pipe.

¢

The adapter installs directly onto the sink tailpiece as

typically shown in Figure 21.

¢

Locate so drain tubing from the faucet makes a

straight run to the adapter, without dips, loops, low spots

or kinks.

NOTE:

Consult a plumber if you are not familiar with

plumbing procedures.

1.

Use a ferrule and nut to assemble the drain tubing

connector to the drain adapter. Turn the connector to

about 45° from the 12:00 position, as shown (to 10:00 or

2:00 position as needed). Tighten the nut securely.

2.

Carefully disassemble the sink drain pipe and clean

the tailpiece to assure a leak-tight fit.

3.

Install the drain adapter onto the sink tailpiece, using

a ferrule and nut. Snug the nut, but do not tighten.

4.

Assemble the p-trap to the drain adapter, and other

drain pipe fittings as required (check codes) to complete

the drain run.

5.

Tighten all connections, but do not overtighten and

break plastic fittings.

NOTE:

Codes in the state of Massachusetts require

installation by a licensed plumber, and do not permit the

use of a saddle valve. For installation, use plumbing code

248-CMR of the Commonwealth of Massachusetts.

FIGURE 21

drain adapter

ferrule

nut

nut

ferrule

drain tubing

connector

sink

tailpiece

2:00

10:00

45°

Check local codes

for approval

B – WASTE WATER CONNECTION

(using drain adapter)

cold

water

A – WATER SUPPLY CONNECTION

(using saddle valve)

Check local codes

for approval

handle

valve

seal

clamp X

clamp Z

ferrule

nut

insert

use to

connect tubing

pre-drill

1/8” hole for

iron pipe

nut (2)

not req’d with all

types of clamp Z