7

INSTALL THE FAUCET

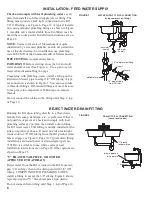

FIGURE 3 - FAUCET INSTALLATION

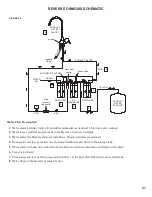

FIGURE 4 - TUBING CONNECTIONS

wire will be connected to

electronics in manifold

(ERO-385E) or

Hydrolink Plus

®

RO

Module in manifold

(HERO-385Plus)

electronics ring

u

o-ring

u

washer

¤

¤

Model ERO-385 only

u

Model ERO-385E or

HERO-385Plus only

spout

lever

faucet

1-1/4” dia. hole

spacer

u

bushing

washer

hex nut

steel washer

(large)

3/8” black

tubing,

30” long

1/4” red tubing from RO

(via high recovery flow

control)

1/4” barb

fitting

3/8” barb

fitting

tubing connector

1/4” to 3/8”

Select one of the following places to install the faucet.

Be sure there's room underneath so you can make the

needed connections.

u

In an existing sink spray attachment hole.

u

Drill a hole in the sink top.

u

Drill a hole in the countertop, next to the sink.

NOTE:

Looking at Figure 3, be sure the faucet base will

fit flat against the surface at the selected location so the

o-ring will seal.

1.

Do not connect drain tubing until Step 1, top of Page

10.

2.

For Model ERO-385, slide the chrome washer onto

the faucet stud, Figure 3.

3.

For Model ERO-385E or HERO-385Plus, snap the

o-ring in the groove on the bottom of the ring and slide

the monitor ring onto the faucet stud. The monitor ring

LED wire must be routed through the sink or countertop

hole and through the spacer, if used, Figure 3.

NOTE:

If you will route the RO drain tubing directly to

the drain point, disregard Steps 4 and 6 and do Step 1 on

top of Page 10.

4.

Take the 30" length of 3/8" black tubing and push

one end onto the 3/8" faucet barb fitting, Figure 4.

5.

Move the RO system into position, under the sink.

(Referring to Page 8, hang the system on cabinet wall, or

lay on the floor surface, as desired.)

6.

Route the 1/4" red tubing from the bottom, up

through the faucet mounting hole. Push the end of the

tubing onto the 1/4" barb fitting.

7.

Work tubing and the faucet stud down, into the

mounting hole.

8.

On the underside of the sink or countertop, install

the spacer (Model ERO-385E or HERO-385Plus only),

plastic bushing, flat washer, and hex nut. Slide the large

steel washer in place, between the bushing (or spacer)

and the bottom of the sink or countertop. Then, tighten

the hex nut securely. Make sure that the LED wire is in a

position so that it will not be cut, pinched or kinked

before tightening the faucet assembly.

9.

Thread the tubing connector onto the bottom of the

faucet stud.

10.

Push the end of the 3/8" blue tubing from the RO,

into the tubing connector installed in Step 9.

NOTE:

See tubing connection procedures on Page 9. For

ease of service and maintenance, keep tubing lengths

long enough so removal of the RO system from under

the sink is possible.

3/8” blue

tubing

from RO