21

ECOWATER

S

Y

S

T

E

M

S

Service Information

CHECKING

THE MODEL CODE ENTRY (See page

12)

Unplug the transformer at the electrical outlet, then

plug it in again. A “beep” will sound, then the model

code displays for a few seconds. The test number

will then display for a few seconds, followed by the

present time display.

CHANGING

THE MODEL CODE

IMPORTANT: READ page 12 BEFORE CHANGING

THIS CODE.

1. Enter the secondary mode...press SELECT and

hold for 3 seconds.

2. Again, press SELECT and hold for 3 seconds.

The current model code setting will display.

3. Use the (

↑

) or (

↓

) keypad to display the desired

model code.

4. Press SELECT to set.

5. Reset the timer (page 12) and reselect other de-

sired options.

MANUAL INITIATED ELECTRONIC DIAGNOSTICS

1.

To enter diagnostics, press the SELECT keypad

and

hold

for 3 seconds.

A.

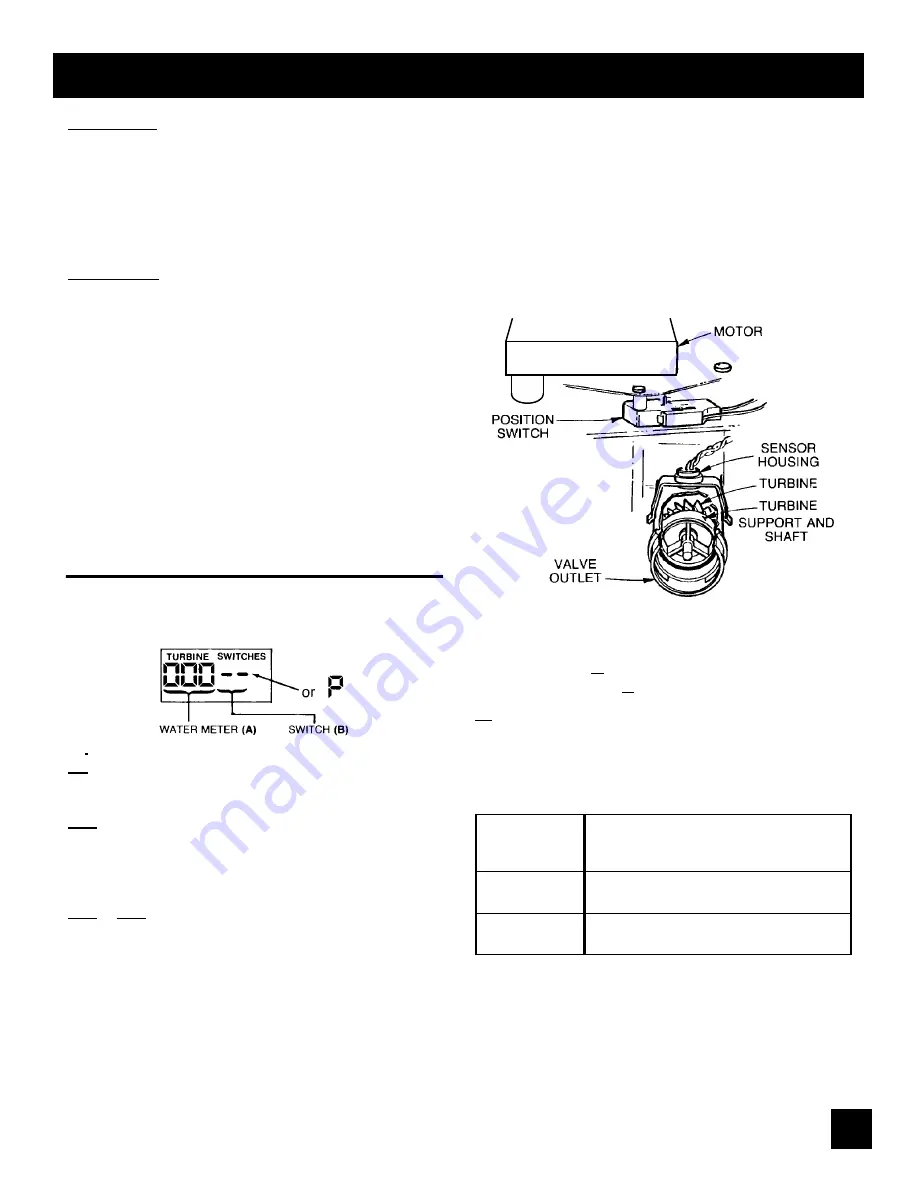

The first 3 digits indicate water meter operation as

follows.

000 (steady) = conditioned water not in use...no flow

through the meter.

--open a nearby CONDITIONED WATER faucet--

000 to 199 (continual) = repeats display for each gal

lon of water passing through

the meter.

If you don’t get a reading in the display, with a faucet

open, pull the sensor housing from the valve outlet

port. Pass a small magnet back and forth in front of

the sensor. You should get a reading. If you

do get

a reading

, disconnect the outlet plumbing and

check the turbine for binding. If you

don’t get a

reading

, the sensor is probably defective. CAU-

TION: BE SURE TO TURN OFF WATER BEFORE

YOU DISCONNECT PLUMBING.

Use the RECHARGE keypad to manually advance

the valve into each cycle and check correct switch

operation (step

B

), and observe the valve position

indicator bars (step

C).

B.

The letter (P) and dash or dashes indicate posi-

tion switch operation. The letter shows if the switch

is closed. A dash shows when the switch is open.

NOTE:

The position switch is closed when the plung-

er is depressed, open when extended.

CORRECT

SWITCH

DISPLAYS

VALVE CYCLE STATUS

-- --

valve in service, fill, brining, back-

wash or fast rinse position

-- P

valve rotating from one position to

another