27

ECOWATER

S Y S T E M S

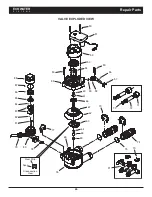

Repair Parts

To order parts, call your local EcoWater dealer or go to

www.ecowater.com to locate a dealer in your area.

VALVE PARTS LIST

Key

No. Part No.

Description

50

7338111

Screw, #6-19 x 1-3/8” (2 req.)

51

7281291

Motor

52

7337474

Motor Mount

53

7284964

Cam & Gear

54

7030713

Switch

–

7332157

Drain Hose Adaptor Kit

(includes Key Nos. 55-59)

55

á

Clip, Drain

56

á

Drain Hose Adaptor

57

á

Hose Clamp

58

á

O-Ring, 5/8” x 13/16”

59

á

Flow Plug, 2.2 gpm

–

7129716

Seal Kit (includes Key Nos. 60-65)

60

á

O-Ring, 7/16” x 5/8”

61

á

O-Ring, 3/4” x 15/16”

62

á

O-Ring, 3-3/8” x 3-5/8”

63

á

Rotor Seal

64

á

O-Ring, 3/8” x 9/16”

65

á

Seal, Nozzle & Venturi

66

7082087

Wave Washer

67

7199232

Rotor & Disc

68

7092642

Plug, Drain Seal

69

7129889

Spring

70

7116713

Clip, 3/4”, single (4 req.)

7336397

Clip, 3/4”, pack of 20

–

7344146

Copper Tube Kit, 3/4”,

Ù

(includes

10 ea. of Key Nos. 71-73)

71

0507369

Installation Nut

Ù

(2 req.)

72

0507615

Installation Tube, 3/4”

Ù

(2 req.)

73

7170335

Washer

Ù

(2 req.)

Key

No. Part No.

Description

74

7278442

Installation Adaptor, 3/4”,

single (2 req.)

7336606

Installation Adaptor, 3/4”, pack of

10 (includes 10 ea. of Key No. 75)

75

7170288

O-Ring, 15/16” x 1-3/16”,

single (2 req.)

7336402

O-Ring, 15/16” x 1-3/16”,

pack of 20

76

7082053

Valve Body

77

7081201

Retainer, Nozzle & Venturi

78

7170319

O-Ring, 1/4” x 3/8” (2 req.)

79

1202600

Nut - Ferrule

–

7257454

Nozzle & Venturi Assembly

(incl. Key Nos. 77, 78 & 80-88)

80

7081104

Housing, Nozzle & Venturi

81

7095030

Cone Screen

82

1148800

Flow Plug, .3 gpm

83

7114533

Nozzle & Venturi Kit w/Gasket

7204362

Gasket only, single

7336486

Gasket only, pack of 20

84

7084607

Flow Plug, .15 gpm

85

7146043

Screen

86

7167659

Screen Support

87

7170262

O-Ring, 1-1/8” x 1-3/8”, single

7336436

O-Ring, 1-1/8” x 1-3/8”, pack of 20

88

7199729

Cap

89

7337466

Valve Cover

90

7074123

Screw, #10-14 x 2” (5 req.)

91

7278434

Bypass Valve, 3/4”, Clip Style

Ù

(includes 2 ea. of Key No. 75)

¢

7129871

Bypass Valve, 3/4”, Threaded

Ù

(includes 2 ea. of Key No. 75)

¢

Not illustrated.

Ù

Not included with the system.