5

ECOWATER

S Y S T E M S

Media Loading (Models ETF2300EIV10 & ETF2300EIV12)

MEDIA LOADING

Models ETF2300EIV10 & ETF2300EIV12

, as manu-

factured, have no media other than quartz gravel at

the bottom of the tank (See table on Page 3 for

amounts). Before plumbing these units, load media:

1

. Move the filter into installation location and set it on

a flat, level surface. If a twin installation, keep

tanks separated for ease of service.

2

. Take off the unit’s top cover and unplug the wiring

connections between the valve and the control

board (PWA).

3

. Remove retainer clips and clamp sections from the

tank neck and carefully lift the valve off the tank.

4

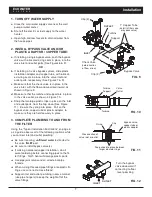

. Check the height of the riser pipe as shown in

Figure 3. If riser pipe is more than 1/2” above the

top distributor, make sure that bottom distributor is

below gravel at the bottom of the tank. It may be

necessary to lay the filter on its side to move gravel

to one side, hold the bottom distributor at the bot-

tom center of the tank and stand the unit back up.

Level gravel after checking.

5

. After confirming the riser pipe height, remove the

top distributor from the tank neck, leaving the bot-

tom distributor (including riser pipe) in place, cen-

tered in the tank.

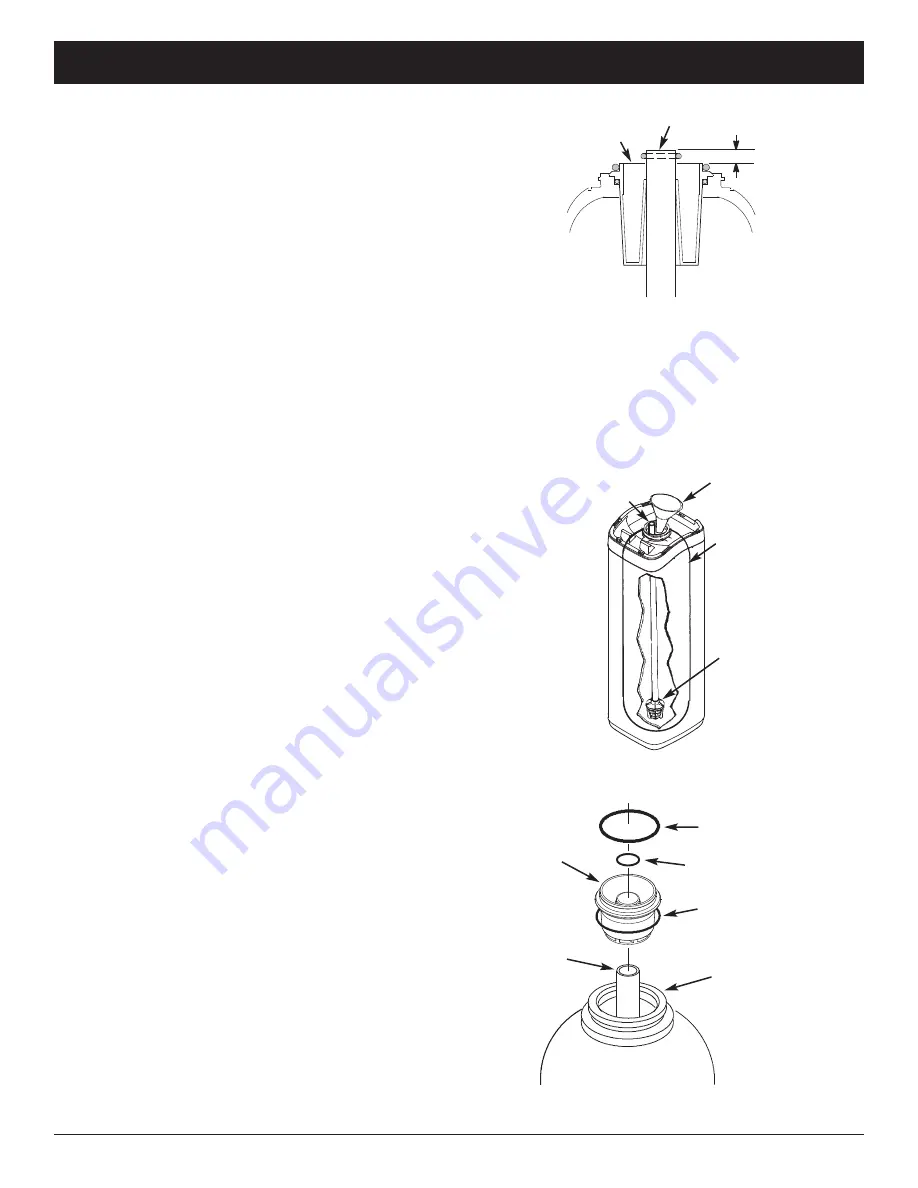

6

. Cover the top end of the riser pipe with a clean

rag, to keep media out (See Fig. 4).

7

. Using a larger neck funnel, add the necessary

amount of media.

8

. Flush the tank opening with water to clean media

particles from the top of the tank. Uncover the bot-

tom distributor stand tube.

9

. Fill the tank with water, up to the top of the tank.

IMPORTANT:

Be sure to fill with water. This will elim-

inate air space, wet the media and pre-

vent excessive air-head pressure when

filter is pressurized.

10

. Install the o-ring seals and top distributor exactly

as shown in Figure 5. Place the small o-ring at

the top of the riser pipe, where shown in Figure 3.

If the o-rings need lubrication, use a high quality

silicone grease.

11

. Lower the valve assembly onto the tank, centering

over the riser tube. Push downward, against the

o-ring, and install the clamp sections, securing

with the retainer clips.

12

. Reconnect the wiring between the valve and the

control board (PWA).

13

. Verify that the drain flow plug (See Key No. 59 on

Page 35) is appropriately sized for the media

used. If necessary, install a different flow plug.

FIG. 5

Top

Distributor

Bottom

Distributor

Riser Pipe

O-Ring, 2-7/8” x 3-1/4”

Make sure o-ring

sealing surfaces

are clean

O-Ring, 13/16” x 1-1/16”

O-Ring, 2-3/4” x 3”

Top Edge of

Top Distributor

Riser Pipe

0” to 1/2”

Note:

Resin tank height can vary somewhat within manu-

facturing tolerance. So that the bottom distributor riser pipe

has proper clearance with inside valve porting, check for

the correct length, as shown above. Cut the riser pipe if

needed to adjust the length. Be sure to remove burrs and

sharp edges.

FIG. 3

FIG. 4

Funnel

Plug or cover top of

riser pipe

Tank

Make sure

bottom distributor

is centered