9

ECOWATER

S Y S T E M S

Description of Operation

Service water enters the filter and passes through air

captured at the top of the mineral tank. Dissolved iron

is oxidized and then removed by the media in the

tank. When the system recharges, it first backwash-

es the contaminants to the drain, then empties the

tank of water, replacing it with air drawn through the

aspirator. When the system returns to "service", the

water pressure will compress the air in the mineral

tank and leave an 8-14" head of air on the top of the

tank.

Care is taken at the factory to keep your water filter

clean and sanitary. Materials used to make the filter

will not infect or contaminate your water supply, and

will not cause bacteria to form or grow. However,

during shipping, storage, installing and operating,

bacteria could get into the filter or media. For this

reason, sanitizing as follows is suggested* when

installing.

1

. Obtain pharmaceutical grade 12% hydrogen perox-

ide solution. One quart (0.95 L) is required for a

10" filter, 2 quarts (1.9 L) for a 12" filter.

2

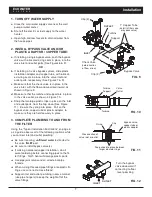

. Remove air inlet screen from check valve on the

valve’s nozzle & venturi assembly (See Figure 14).

3

. Connect a length of 3/8 I.D. tubing to the barb on

the aspirator check valve (See Figure 15).

4

. Insert the free end of the tubing into the hydrogen

peroxide container.

5

.

Start a recharge:

From the rolling status screens,

press the SELECT (

¡

) button to display the

Main

menu

. Make sure

Recharge

is highlighted, then

press SELECT (

¡

). Press DOWN (

6

) to scroll to

Recharge now

, then press SELECT (

¡

) twice.

You should hear the valve motor run as the filter

begins recharging. The filter will backwash for 15-

17 minutes, then advance automatically to the

“aspirate” position. It will draw the hydrogen perox-

ide into the filter and pass it through the zeolite

media, cleaning and sanitizing the media.

6

. Allow the filter to draw air for the remainder of the

time in the “aspirate” cycle after the hydrogen per-

oxide has been drawn into the filter.

7

. The filter will return to “service” automatically when

the “aspirate” cycle is complete.

8

. Remove tubing and reinstall the aspirator inlet

screen onto the barbed fitting on aspirator check

valve.

9

. Cleaning/sanitizing process is complete.

*

NOTE:

Sanitizing is recommended by the Water Quality

Association for disinfecting. On some water sup-

plies, they suggest periodic sanitizing.

FIG. 14

FIG. 15

Valve nozzle &

venturi assembly

Valve nozzle &

venturi assembly

Place other end of tube in

hydrogen peroxide solution

Check valve

3/8” barb

Remove air

inlet screen

Check valve

3/8” barb

Connect 3/8” I.D.

tubing to barb

ECOWATER

S Y S T E M S

Sanitizing Procedure