·14·

Maintenance

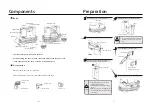

Cleaning of inlet air sponge and filtering

sponge

Rinse the inlet air sponge and filtering sponge

after use, and replace them if they are damaged.

Inlet air sponge.

( At the bottom of the sewage bucket )

Filtering sponge

(At the bottom of the water

bucket)

* It is more convenient

to pick up with

tweezers.

Air dry after cleaning.

Install the parts back to the machine after

maintenance.

After maintenance, keep in a dry place at room

temperature, and avoid direct sunlight.

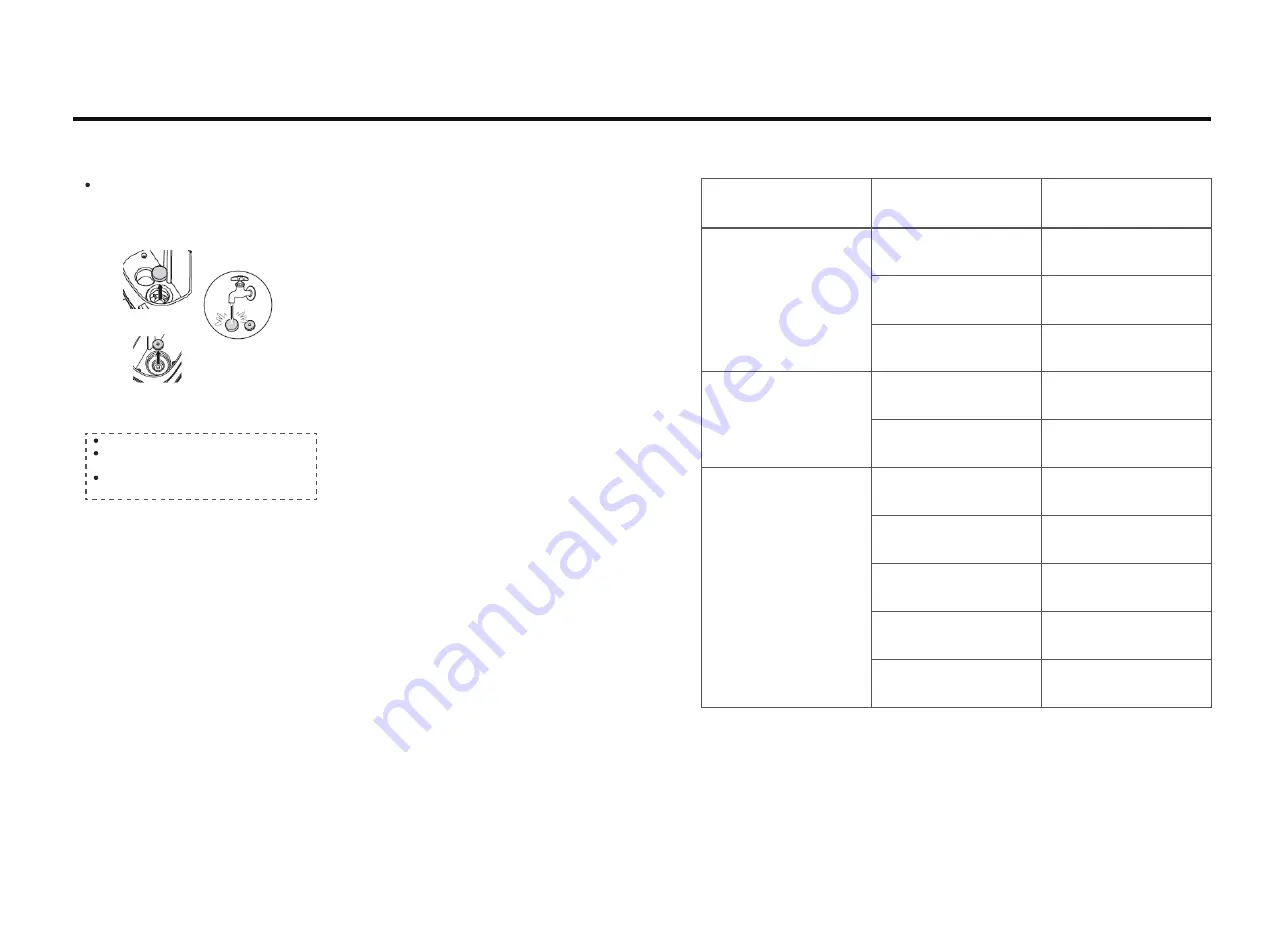

Fault and Handling

In the event of exceptions in use, read this manual carefully and confirm the

following points before repair.

Status

Fault cause analysis

Handling

The machine does not

work after the switch

is turned on

The machine does not

work after the switch

is turned on

The plug is not properly connected

and loose, resulting in poor contact.

The internal line or power cord is

broken.

The machine set overheats and the

protective device operates.

Turn off the power and plug it again.

Call the repair telephone.

Refer to the instructions for protective

device.

The nozzle is blocked.

The handle or pump is damaged.

Remove the water sucker and rinse the

nozzle with clean water.

Call the repair telephone.

There is no dust

collection or the

suction is very

weak

The power switch is not turned on.

The sewage bucket is full, causing the

floating ball to work.

The hose is abnormal.

The sewage bucket is not installed

in place.

The inlet air sponge is blocked

Turn on the power switch.

Clean up the sewage and use it again.

Check the hose for cracks, breaks and

clogs.

Install the sewage bucket properly.

Clean or replace the sponge.

When we are unable to solve the problems, please consult thestore or customer service.

·15·

Summary of Contents for WDV01

Page 1: ...SPOT CLEANER ...