regulator. The flue outlet pressure (measured between

the furnace and draft regulator, or the oil burner

mounting plate over-fired draft access port. fig. 2) should

be set to -0.02 in. w.c.

8. OPTIONAL SIDE WALL VENTING

Certain HML-C and HMLV-C furnace models are

manufactured to be installed as sidewall vented units.

Please refer to Direct Venting Instructions, P/N

240006979 included with the Vent Kit for details. Sidewall

Venting (

Direct Venting

) requires the use of specific oil

burners; the Beckett AFII, or the Riello 40BF. Please

refer to Appendix A, Tables A2, and A4.

Note: Sidewall venting requires special attention to

combustion air supply. There is no natural draft in the

venting system between furnace cycles; therefore, if the

indoor pressure is negative relative to the outdoors, the

vent terminal becomes a point of infiltration. This could

lead to oil odour control problems. This problem is

rectified by the use of ducted outdoor air for combustion

(semi-sealed combustion), using the Beckett AFII or

Riello 40BF oil burner. See Direct Vent Instructions

supplied with the Vent Kits.

9a. FAN TIMER BOARD AND LIMIT CONTROL

(FIG. 4) (page 22)

The Electronic Fan Timer integrates control of all burner

and circulator fan operations. This control is the central

wiring point for most of the electrical components in the

furnace. The

United Technologies 1158-120 (HML-C)

has an adjustable fan on time that is set by selecting the

dipswitch combination displayed in Chart 1. This fan on

delay can be set at 1, 2, 4 or 6 minutes. This provides a

delay between the burner ignition and blower start-up to

eliminate excessive flow of cold air when the blower

comes on. The

United Technologies 1158-120 (HML-

C)

has an adjustable fan off time of 30, 60, 90 or 120

seconds displayed in Chart 1. The fan off delay time

starts when the burner motor is de-energized at the end

of a call for heat. Blower shutdown is delayed to remove

any residual heat from the heat exchanger and improve

the annual efficiency of the furnace.

The electronic fan timer board works in conjunction with

snap disc limit controls, which perform a safety function,

and breaks power to the oil burner primary control, which

shuts off the burner if the furnace over-heats. The limit

control is thermally operated and automatically resets.

The limit control is factory installed, pre-set and is not

adjustable.

If the limit control opens with the

United Technologies

1158-120 (HML-C)

electronic fan control

,

the circulating

fan will be energized as well. When the limit closes, the

fan off timer will begin. At the end of the fan off time cycle

the burner will be energized, initiating a normal burner

cycle.

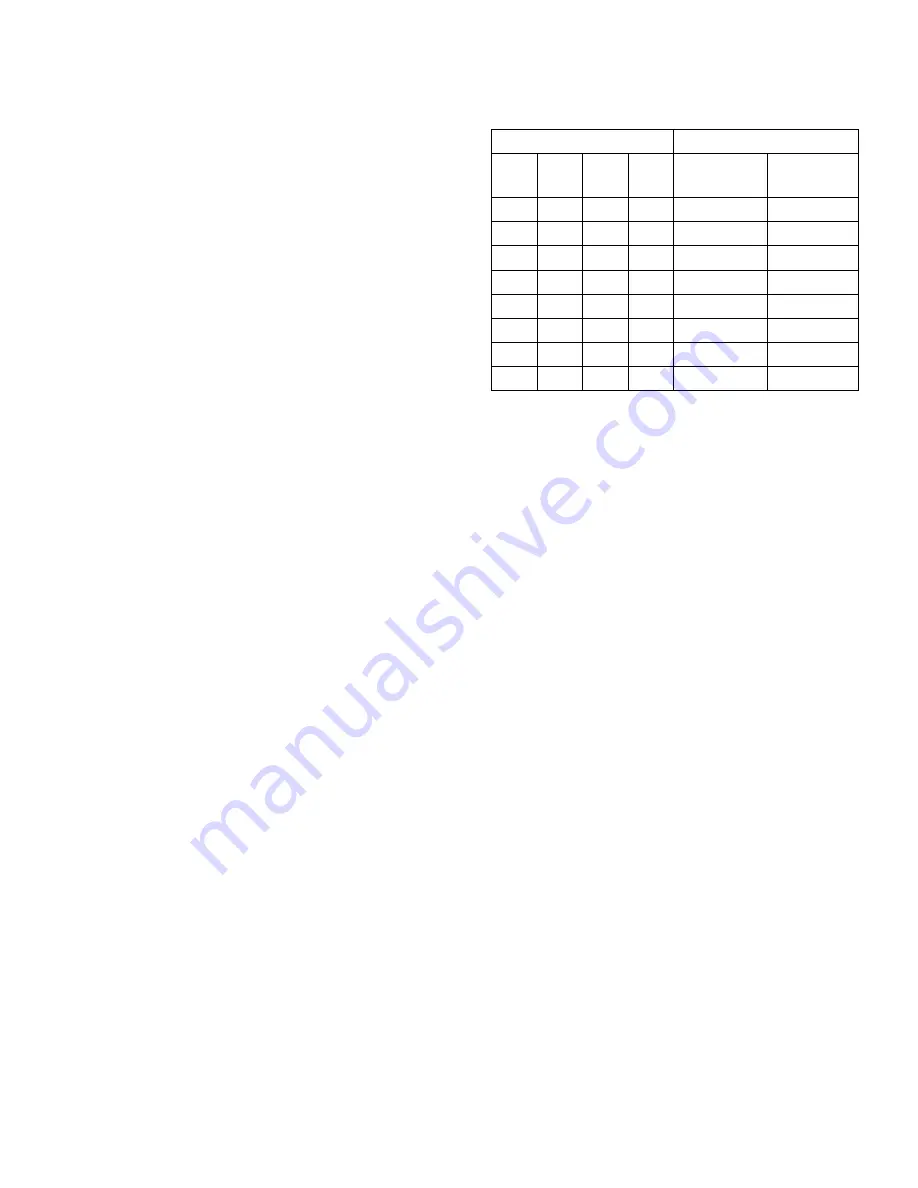

CHART 1

United Technologies 1158-120 (HML-C)

Dip Switch Position

Blower Delay Times

1 2 3 4

On

Seconds

Off

Minutes

Off Off

30

On Off

60

Off On

90

On On

120

Off

Off

1

On

Off

2

Off

On

4

On

On

6

9b. FAN TIMER BOARD AND LIMIT

CONTROL (FIG. 5) (page 22)

The

United Technologies 1168-1 ECM (HMLV-C)

tap board has an adjustable fan on/off delay that

must be adjusted in accordance with the furnace

input rating (nozzle size). Refer to Table A-10 (pg

15) for ECM blower set-up.

10. ELECTRICAL CONNECTIONS

The furnace is listed by the Canadian Standards

Association under the NRTL (North American)

Standard. It is factory wired and requires minimal

field wiring. All field wiring should conform to

CAN/CSA C22.1 Canadian Electrical Code, Part 1,

and by local codes, where they prevail. In the United

States, the wiring must be in accordance with the

National Fire Protection Association NFPA-70,

National Electrical Code, and with local codes and

regulations.

The furnace should be wired to a separate and

dedicated circuit in the main electrical panel;

however, accessory equipment such as electronic

air cleaners and humidifiers may be included on the

furnace circuit. Although a suitably located circuit

breaker can be used as a service switch, a separate

service switch is advisable. The service switch is

necessary if reaching the circuit breaker involves

becoming close to the furnace, or if the furnace is

located between the circuit breaker and the means

of entry to the furnace room. The furnace switch

(service switch) should be clearly marked, installed

in an easily accessible area between the furnace

and furnace room entry, and be located in such a

manner to reduce the likelihood that it would be

mistaken as a light switch or similar device.

The power requirement for the HML-C and HMLV-C

models is: 120 VAC, 1 Ø, 60 Hz., 12A.

Accessories requiring 120 VAC power sources such

as electronic air cleaners and humidifier

30173 Rev B 4/29/2008

5

Summary of Contents for HML-C

Page 33: ...30173 Rev B 4 29 2008 33...

Page 34: ...30173 Rev B 4 29 2008 34...

Page 35: ...30173 Rev B 4 29 2008 35...