30318 R4 9/9/2005

9

trunk ducts. These systems may require

modification to provide some resistance

to the airflow to prevent over-amping of

the direct drive blower motor. Selecting a

lower blower speed may correct this

problem.

Direct drive blower speeds are adjusted

by changing the "hot" wires to the motor

winding connections. Please refer to

wiring diagram in Appendix B or the

wiring diagram label affixed to the

furnace.

THE NEUTRAL WIRE

(normally the white wire) IS NEVER

MOVED TO ADJUST THE BLOWER

SPEED

.

DO NOT CONNECT POWER LEADS

BETWEEN MOTOR SPEEDS. THE

NEUTRAL WIRE MUST ALWAYS BE

CONNECTED TO THE MOTOR'S

DESIGNATED NEUTRAL TERMINAL.

It is possible and acceptable to use a

single blower speed for both heating and

cooling modes. The simplest method to

connect the wiring from both modes is to

use a "piggy-back connector"

accommodating both wires on a single

motor tap. It is also acceptable to

connect the selected motor speed with a

pigtail joined to both heating and cooling

speed wires with a wire nut. As a safety

precaution against accidental

disconnection of the wires by vibration, it

is advisable to secure the wire nut and

wires with a few wraps of electricians

tape.

If the joining of the blower speed

wiring is done in the furnace junction

box, tape

off both ends of the unused

wire.

DISCONNECT THE POWER SUPPLY

TO THE FURNACE BEFORE

OPENING THE BLOWER ACCESS

DOOR TO SERVICE THE AIR FILTER,

FAN AND MOTOR. FAILURE TO

SHUT OFF POWER COULD ALLOW

THE BLOWER TO START

UNEXPECTEDLY, CREATING A RISK

OF DEATH OR PERSONAL INJURY.

Do not use the blower speed wires as

a source of power to accessories as

electronic air cleaners and humidifier

transformers. The unused motor taps

auto-generate sufficiently high

voltages to damage accessory

equipment. Use the terminals

provided on the electronic fan timer.

Do not start the burner or blower fan

unless the blower access door is

securely in place.

Additional ST9103 Fan Timer Control

information is in Appendix A, Tables, and

in Appendix B, Wiring Diagrams.

HUMIDIFIER

A humidifier is an optional accessory

available through most heating supplies

outlets. Installation should be carried out

in accordance with the humidifier

manufacturer's installation instructions.

Water or water droplets from the

humidifier should not be allowed to come

into contact with the furnace heat

exchanger. Do not use direct drive motor

connections as a source of power for

120 VAC humidifiers and humidifier

transformers.

OIL BURNER

The oil burner must align properly with

the cerafelt fiber chamber (firepot). The

cerafelt fiber chamber is initially quite

soft, but hardens and becomes quite

brittle after the first firing. The firepot is

held in place by a retaining bracket;

however, it is possible for the firepot to

shift if subjected to rough handling during

transit.

BEFORE OPERATING THE

FURNACE CHECK BURNER

ALIGNMENT WITH COMBUSTION

CHAMBER. THE END CONE OF THE

AIR TUBE MUST BE CENTRED TO

THE ACCOMODATING RING

PROVIDED IN THE DESIGN OF THE

COMBUSTION CHAMBER. ADJUST

ALIGNMENT AS NECESSARY

BEFORE THE FIRST FIRING.

OIL BURNER NOZZLES

WML-C AND MPL-B furnaces are

certified for multiple firing rates, ranging

from approximately 58,000 to 85,600

BTU/hr. on the WML-C and 85,500 to

123,000 BTU/Hr. on the MPL-B By

changing the oil burner nozzle within the

specific model range, and temperature

rise, the furnace may be fired at an ideal

rate for a wide range of structures.

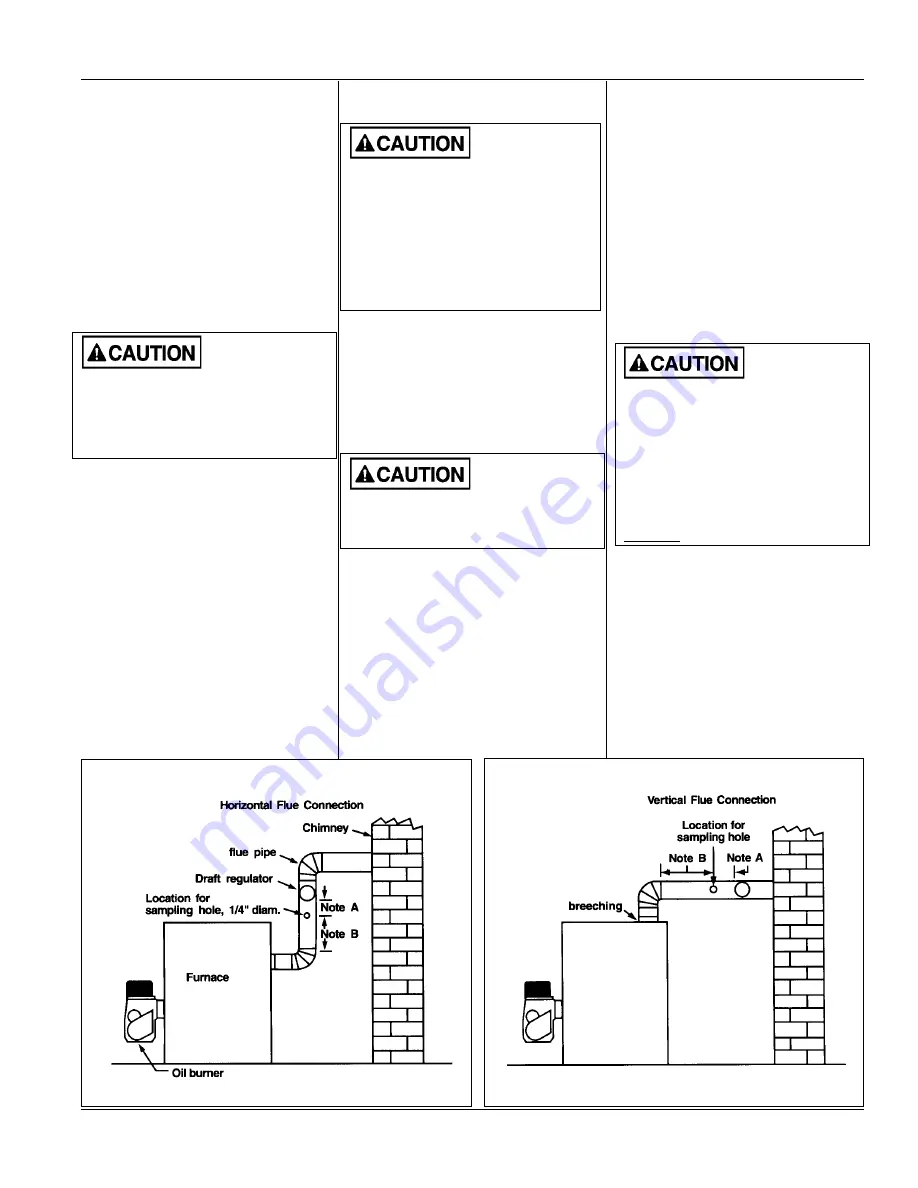

Figure 4: Horizontal Smoke Test Port Location

Figure 5: Vertical Smoke Test Port Location

Summary of Contents for MPL-B

Page 17: ...30318 R4 9 9 2005 17 APPENDIX B WIRING DIAGRAMS Beckett AF Burner Wiring Diagram...

Page 18: ...30318 R4 9 9 2005 18 Beckett AFII Burner Wiring Diagram...

Page 19: ...30318 R4 9 9 2005 19 Riello 40F3 and F5 Burner Wiring Diagram...

Page 20: ...30318 R4 9 9 2005 20 Riello 40BF3 Burner Wiring Diagram...

Page 34: ...30318 R4 9 9 2005 34...

Page 37: ...30318 R4 9 9 2005 37...

Page 39: ...30318 R4 9 9 2005 39 NOTES...