3

1

INST

ALLER Section

(en)

7.

press

again to take the boiler to

minimum power

. Wait for the value of

CO

2

to stabilize and then adjust as described in

step 4 of the procedure (power value = 00);

8.

to exit the function, press the buttons for at least 6 seconds as described in step1.

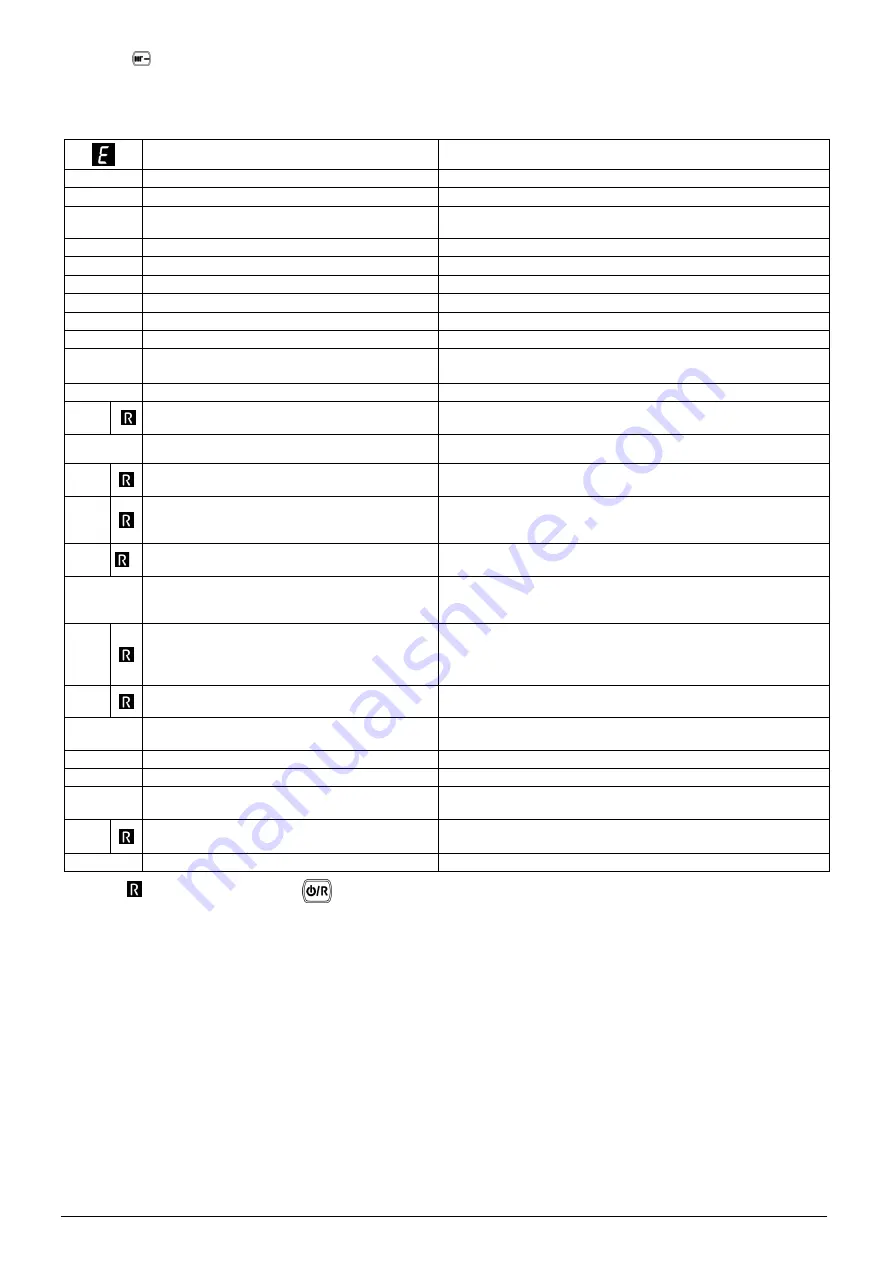

12.5 ERROR MESSAGES AND RESETTING THE BOILER

ERROR description

OPERATION

09

Gas valve connection fault.

Check the cable pcb/gas valve and gas valve plug

10

Outdoor sensor fault .

Check the sensor and the cable

15

Gas valve command fault.

Verify all the cables. Replace the pcb.

Call an authorized SERVICE center

20

Central Heating NTC sensor fault.

Check the sensor and the cable

28

Flue NTC heat exchanger sensor fault

Check the sensor and the cable

40

Return NTC sensor fault.

Check the sensor and the cable

50

Domestic Hot Water NTC sensor fault

Check the sensor and the cable

53

Obstruction in the flue pipe.

Check obstruction on the flue pipe

55

PCB not programmed.

Call an authorized SERVICE centre

83-84-85

86-87

Communication problem between boiler board and

control unit.

Probable short circuit on wiring.

Check the cable between control unit and boiler

109

Pre-circulation alarm (temporary fault).

Check the correct circulation of the water and the pump

110

Safety thermostat tripped due to over temperature

(pump probably blocked or air in heating circuit).

Check the safety thermostat and the cable; check the correct circulation

of the water and the pump

118

Hydraulic pressure too low.

Refill the heating system by open the cold water tap

125

No circulation of the water

(control performed via a temperature sensor).

Check the correct circulation of the water and the pump.

Check the correct connection of the NTC sensor on the pipe

128

Loss of flame.

Check the sensing electrode and the cable, flue recirculation, electrical

continuity between burner and ground, Enable the automatic calibration.

Call an authorized SERVICE centre

130

NTC flue sensor tripped due to over temperature.

Check the thermostat, the correct circulation of the water and the pump.

Check the status of the primary exchanger

131

Thermo fuse tripped due to over temperature.

Check the thermo fuse, the correct circulation of the water and the

pump. Check the status of the primary exchanger. Replace the heat

exchanger.

Call an authorized SERVICE center

133

Ignition failure

Check the correct operation of the condensate trap. Check the sensing

electrode, spark electrode and cable. Check flue recirculation,

electrical

continuity between burner and ground.

Enable the automatic calibration

function.

Call an authorized SERVICE centre

134

Gas supply valve blocked.

Check the gas pressure, sensing electrode, spark electrode and cable,

replace the pcb if it necessary.

Call an authorized SERVICE center

135

Internal error.

Verify all the cables. Replace the pcb.

Call an authorized SERVICE center

160

Fan fault.

Check the fan and the cable

162/317

Incorrect power supply frequency.

Incorrect power supply frequency.

169

Flue pressure switch (contact open)

Check the pressure switch and the cable.

Check obstruction on the flue pipe

164/

384

Fault flame (parasitic flame).

Check the correct operation of the gas valve.

165/385

Input voltage too low.

Check the power supply

for at least 2 seconds. For other error codes not described in the table please contact

To RESET

the boiler press the button

Utica Boiler

at 1(800)

325

-

5479

.

2400

11317

,

REV

D

(

0

7

/

30

/1

6

)

Summary of Contents for UTICA BOILERS MAC-150

Page 10: ...MAC 150 Low Water Pressure Cutoff 10 240011317 REV D 07 30 16...

Page 11: ...MAH 125 Low Water Pressure Cutoff 11 240011317 REV D 07 30 16...

Page 54: ...Coupure de la pression d eau faible 54 240011317 REV D 07 30 16...

Page 84: ...84 S e c t i o n I N S T A L L A T E U R f r 240011317 REV D 07 30 16...

Page 87: ...87 S e c t i o n I N S T A L L A T E U R f r 240011317 REV D 07 30 16...