21

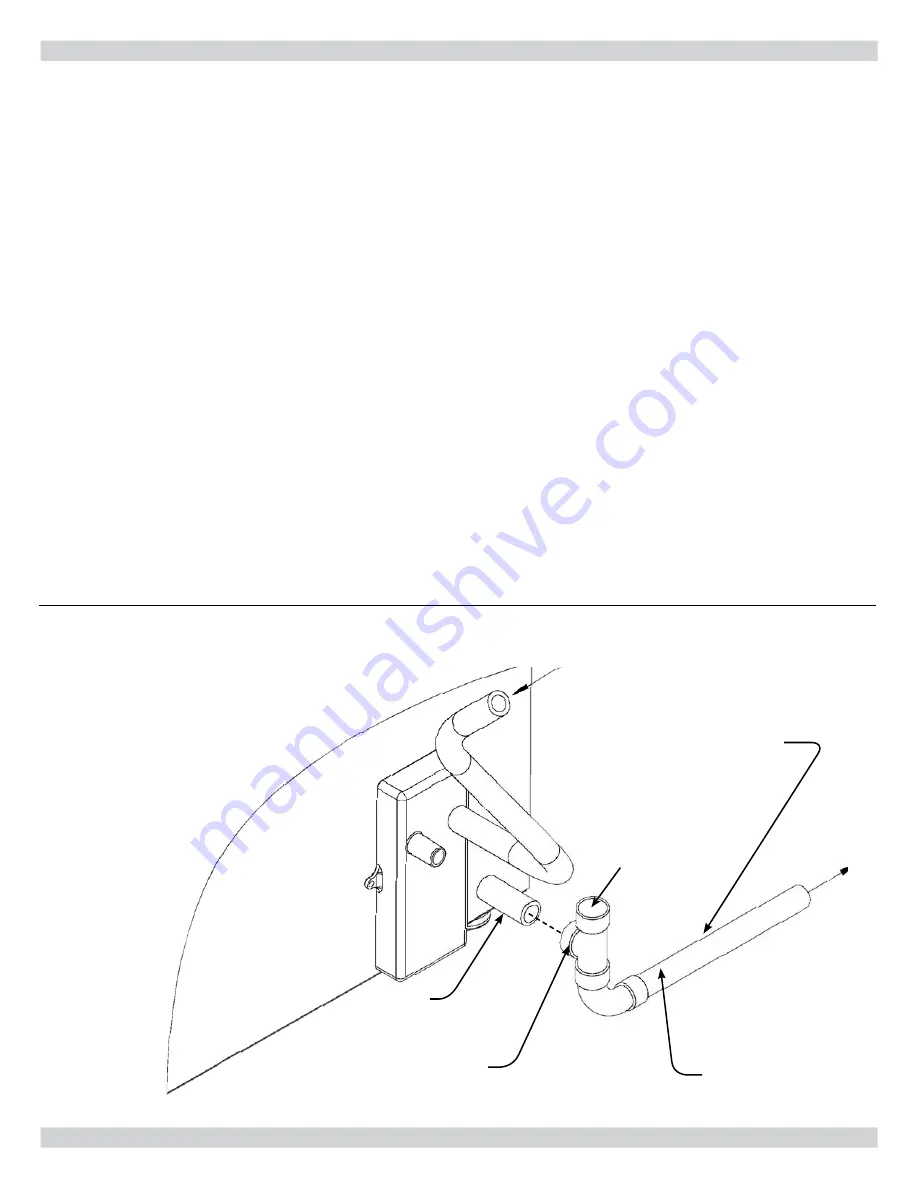

Condensate Drain Piping

Boiler is factory equipped with a condensate trap. An

additional trap is not required and should NOT be used.

1.

Provide ½” PVC condensate drain and

fi

ttings.

Condensate drain to be pitched down to

fl

oor drain at

a minimum of ¼” per foot. Installation shall conform

to requirements of authority having jurisdiction, check

local codes for requirements.

2.

Install ½” PVC tee to over

fl

ow

fi

tting as shown in

Figure 11

.

3.

The ½” diameter schedule 40 PVC or CPVC condensate

drain and pipe

fi

ttings must conform to ANSI standards

and ASTM D 1785 or D2846.

4.

Schedule 40 PVC or CPVC cement and primer must

conform to ASTM D2564 or F493.

5.

In Canada, use CSA or ULC certi

fi

ed schedule 40 PVC

or CPVC drain pipe cement.

6.

Condensate pump with reservoir (not furnished) may

be used to remove condensate to a drain line (sanitary

line) above boiler if

fl

oor drain is not available or is not

accessible.

Figure 11 - Condensate Drain Piping

NEAR BOILER PIPING

Filling Condensate Trap With Water

On initial start up condensate trap must be manually

fi

lled

with water.

Following are the steps required to initially

fi

ll condensate

trap for start up. Steps are only required at initial start up

or if maintenance requires draining of condensate trap.

1.

Disconnect vent condensate drain line from vent pipe

connector on outlet of induced draft blower.

2.

Pour about 1 cup of cold tap water into vent drain line

with funnel.

3.

Excess water should go through over

fl

ow and out

through condensate drain line. Verify proper operation

of drain line (or external condensate pump if used).

4.

Reinstall vent drain line.

Chilled Water Piping

Install boiler, when used in connection with refrigeration

system, so chilled medium is piped in parallel with boiler

with appropriate valves to prevent chilled medium from

entering boiler.

Boiler piping system of hot water boiler connected to

heating coils located in air handling units where they may

be exposed to refrigerated air circulation must be equipped

with

fl

ow control valves or other automatic means to

prevent gravity circulation of the boiler water during cooling

cycle.

FROM BLOWER

TO DRAIN

OPEN

PVC TEE 1/2”SLIP X

1/2” SLIP X 1/2” SLIP

1/2” PVC

CONDENSATE

DRAIN

PITCH DRAIN PIPE

DOWN TO FLOOR

DRAIN AT MINIMUM

1/4” PER FOOT

Summary of Contents for Dunkirk 4 Series

Page 33: ...33 Figure 22 Ladder Diagram for Figure 22 ELECTRICAL WIRING ...

Page 52: ...52 Troubleshooting Chart 1 TROUBLESHOOTING ...

Page 53: ...53 Troubleshooting Chart 2 TROUBLESHOOTING ...

Page 63: ...NOTES ...

Page 64: ...DUNKIRK BOILERS 2201 Dwyer Avenue Utica NY 13501 web site www ecrinternational com ...