15

vIII - COmBUSTION aIR aND vENT PIPE

ture. Termination of the vent should be kept at least 3’

away from vegetation. The venting system shall termi-

nate at least 4’ horizontally from, and in no case above

or below, electric meters, gas meters, regulators, and

relief equipment, or under a deck or porch.

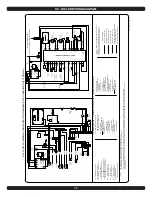

Through the wall vents for Category II and IV appli-

4.

ances and non categorized condensing appliances

shall not terminate over public walkways or over an

area where condensate or vapor could create a nui-

sance or hazard or could be detrimental to the op-

eration of regulators, relief vales, or other equipment.

Where local experience indicates that condensate is a

problem with Category I and III appliances, this provi-

sion shall also apply. If multiple terminations are used,

there must be a minimum of 12” between the exhaust

of one termination and the air intake of the next termi-

nation. See

Figures 1-3

for illustrations.

Installation

ImPORTaNT:

When transitioning from CPVC to

PVC it is recommended to use Weld-On CPVC

724 or other cement approved for CPVC to PVC.

In Canada ULC S636 approved cement must be

used.

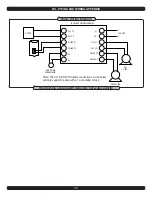

Attach combustion air intake piping to supplied 2” PVC

1.

Intake Connector. Attach vent piping to furnished 2”

CPVC vent pipe. Use a 2” x 3” adapter in both air inlet

and exhaust.

NOTE: All pipe joints are to be water tight.

Working from the boiler to the outside, cut pipe to re-

2.

quired length(s).

Deburr inside and outside of pipe, and remove all

3.

shavings from pipe.

Chamfer outside edge of pipe for better distribution of

4.

primer and cement.

Clean and dry all surfaces to be joined.

5.

Check dry fit of pipe and mark insertion depth on

6.

pipe.

air supply pipe must terminate at the same location as the

exhaust pipe.

Reduce the maximum vent length by 5’ per each 90° el-

bow.

Exhaust air piping to be pitched back to boiler at

1.

minimum ¼” per foot from vent terminals so that all

moisture in vent piping drains to boiler. Pipes must be

pitched continuously with no sags or low spots where

moisture can accumulate and block the flow of flue

gas. Combustion air and vent pipes must be airtight

and watertight.

Consideration for the following should be used when

2.

determining an appropriate location for termination of

combustion air and vent piping:

Comply with all clearances required.

•

Termination should be positioned where vent vapors will

•

not damage plants/shrubs or air conditioning equipment.

Termination should be positioned so that it will not be ef-

•

fected by wind eddy, air born leaves, snow, or recirculated

flue gases.

Termination should be positioned where it will not be

•

subjected to potential damage by foreign objects, such as

stones, balls, etc.

Termination should be positioned where vent vapors are

•

not objectionable.

Put vent on a wall away from the prevailing winter wind.

•

Locate or guard the vent to prevent accidental contact with

people or pets.

Terminate the vent above normal snowline. Avoid loca-

•

tions where snow may drift and block the vent. Ice or

snow may cause the boiler to shut down if the vent be-

comes obstructed.

Under certain conditions, flue gas will condense, form-

•

ing moisture, and may be corrosive. In such cases, steps

should be taken to prevent building materials at the vent

from being damaged by exhaust of flue gas.

The venting system shall terminate at least 3’ above

3.

any forced air inlet (except boiler’s combustion air in-

let) within 10’. The venting system shall terminate at

least 12” from any air opening into any building. The

bottom of the vent shall be located at least 12” above

grade. The vent terminal shall not be installed closer

than 3’ from the inside corner of an “L” shaped struc-