19

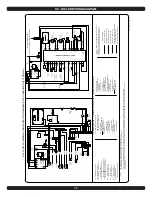

XI - CONTROLS aND aCCESSORIES

This section provides a brief description of the key controls

and accessories found in this boiler. See the Repair Parts

Manual (P/N# 240006107) for illustrations and the Control

Manual and Operation Instructions (P/N# 240006104) for

a detailed sequence of operation and troubleshooting pro-

cedures.

aluminum heat Exchanger

This appliance employs a cast aluminum heat exchanger

that features a monoblock design. The monoblock design

eliminates the need for mating sections and therefore

eliminates leaks between sections. Since the heat ex-

changer is cast of aluminum instead of iron, it has better

heat transfer properties which in turn lead to higher ef-

ficiency and cooler exhaust temperatures. These cooler

exhaust temperatures create condensation of the flue

gas, which would cause corrosion in traditional cast iron

heat exchangers.

main Power Switch

This appliance features a main power switch located on the

display panel. The main power switch is illuminated when it

is receiving power and in the ON position. The only time that

the switch should not be illuminated once the boiler is ready

for use is when the switch is in the OFF position.

modulating Boiler Control

This appliance incorporates an integrated modulating

control that senses the load necessary to heat a structure

and therefore uses less fuel than a conventional fixed fir-

ing rate boiler when there is a lower than peak demand for

heat. The control senses the supply water, return water,

and outside air temperatures if the outside air sensor is

connected and calculates the load on the system. It then

adjusts the firing rate to deliver the amount of heat that is

needed at that particular time.

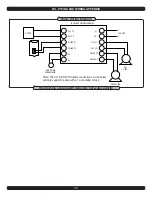

NTC Sensors

The NTC sensors used with this appliance for measuring

supply water, return water, and outside air temperature

are specially configured to operate with the modulating

boiler control.

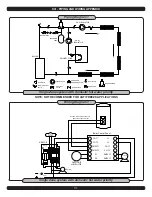

modulating Blower

The modulating blower provides a means of introducing the

gas/air mixture through the burner and into the combustion

chamber where combustion can begin and then out the ex-

haust vent where the combustion products are discharged

to the outdoors. The blower is designed to communicate

with the modulating control to run at variable speeds de-

pendent on the heat load experienced by the heating sys-

tem. The variable speeds create pressures felt by the gas

valve and gas/air mixer that dictate how much fuel is intro-

duced to the combustion process.

Gas Control valve

The gas controls in this boiler have been developed for

domestic heating appliances with premix burners and au-

tomatic direct burner ignition and are suitable for natural

and LP gas. The gas controls perform all the functions

required to safely regulate gas flow to the main burner of

the boiler. The gas valve is directly connected to the gas/

air mixer.

Gas/air mixer

The venturi design of the gas/air ensures that there is al-

ways the correct mixture of air and gas.

modulating Burner

This burner is designed to operate over the full range of

input for this boiler. The burner can operate under normal

(blue flame) and infrared conditions.

Direct Spark Igniter (DSI)

This appliance uses a DSI to ignite the fuel/air mixture in

the combustion chamber and sense flame during opera-

tion. The DSI is a durable, reliable component that resists

breakage due to handling or inadvertent impact with other

objects.

manual Reset Low water Cut Off

This appliance employs a factory installed integral low

water cut off (LWCO) that has to be manually reset if there

is a low water condition. The LWCO senses water through

a probe at the top of the boiler that sends a signal through

the water to ground. If the signal is not sensed through the

ground, the LWCO enters a lockout mode that disables

the appliance. If the LWCO is in normal mode a red indi-

cator light is illuminated on the LWCO panel in the boiler.

During a low water condition, the red light goes out and

the LWCO and control reset buttons on the display panel

must be depressed to reset the LWCO.