82

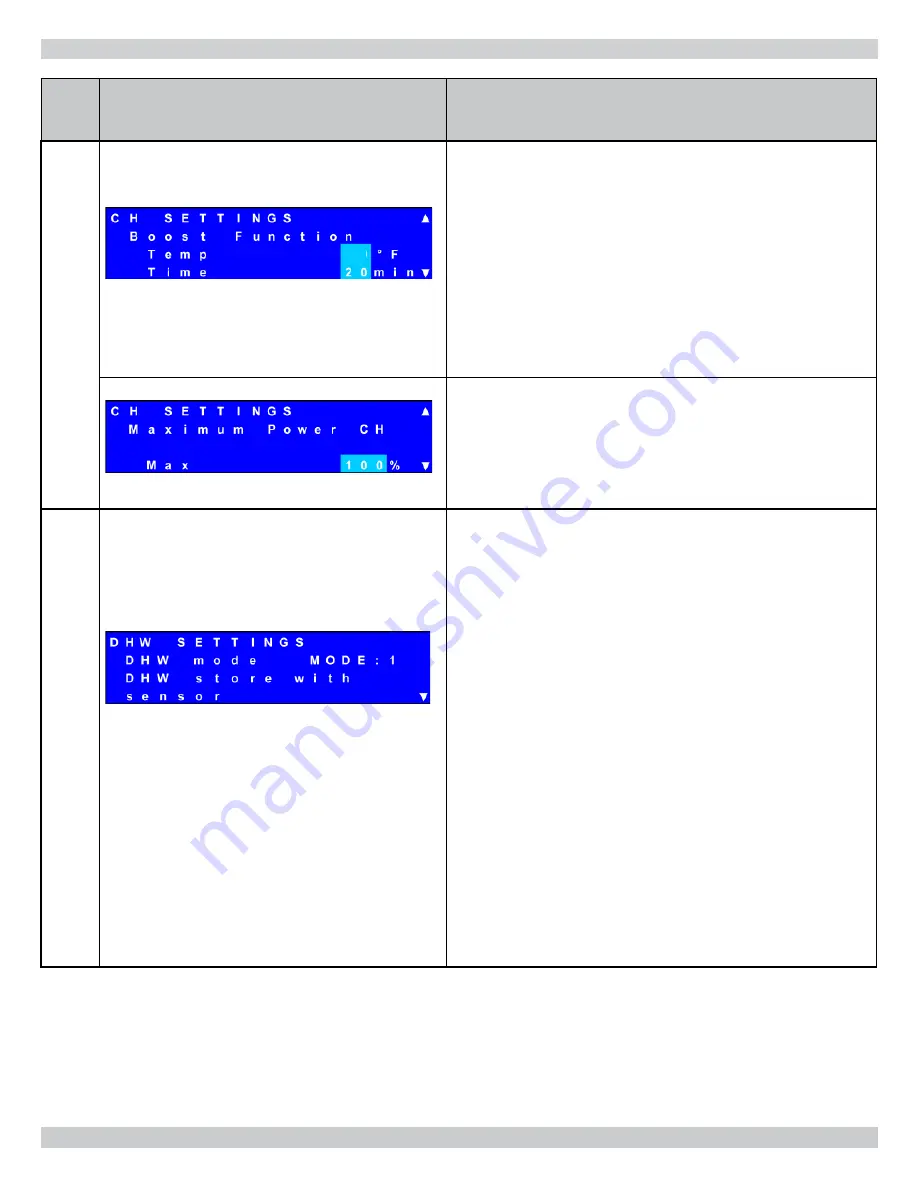

User Interface Display

Explanation

CH Settings

Outdoor reset boost function increases CH set point by

increment (‘Temp’) if CH demand continues beyond pre-set

time limit (‘Time’).

CH set point will continue to increase until set point reaches

195°F / 91°C

Allowable Temperature Increment: 0..36 °F (0..20 °C)

Default Temperature increment: 0 °F (10 °C)

Allowable Time Delay: 1..120 minutes

Default Time Delay: 20 minutes

Maximum boiler power in CH mode limited by adjusting

‘Maximum Power CH’ setting. Boiler will not exceed this

value while operating in CH Mode.

Allowable Range: 1..100%

Default Setting: 100%

DHW Settings

Two DHW modes are available

• DHW Mode = 0 ‘No DHW

• DHW Mode is disabled

• The DHW thermostat input is ignored and the DHW

pump is not used.

•

DHW Mode = 2 ‘DHW Store with Thermostat’

• Boiler reacts to DHW demand when DHW thermostat

input closes.

• Boiler modulates to meet DHW demand similar to CH

Mode except DHW set point is used. DHW set point set

in Settings’ submenu found in 'User Menu’.

• Simultaneous CH & DHW demands handled using DHW

Priority Timing. See ‘DHW Maximum Priority Time’

setting below.

Note:

• Outdoor reset function disabled while operating in DHW

Mode.

• Typical when using a DHW indirect storage tank.

• After DHW demand satis

fi

ed, boiler enters post purge

mode and DHW pump continues to run for 15 seconds.

0

APPENDIX A - CONTROL MODULE

Summary of Contents for Olsen OLSSC-299

Page 47: ...47 13 TROUBLE SHOOTING ...

Page 51: ...51 13 TROUBLE SHOOTING ...

Page 53: ...53 13 TROUBLE SHOOTING ...

Page 62: ...62 Supply Water Temperature Sensor Resistance Chart 13 TROUBLE SHOOTING ...

Page 84: ...ECR International Inc 2201 Dwyer Avenue Utica NY 13501 web site www ecrinternational com ...