35

APPENDIX A - CONTROL MODULE

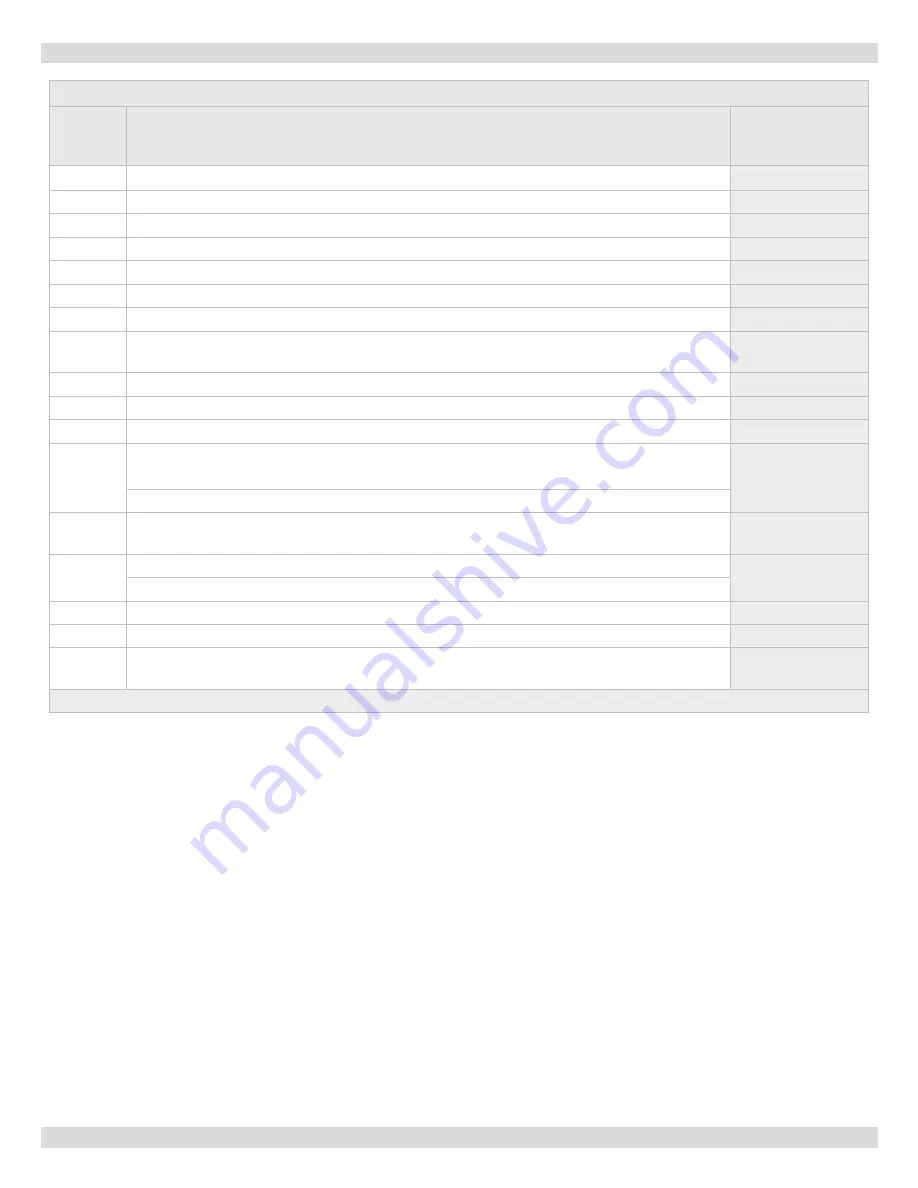

Table 8 - Troubleshooting Error Codes

Error

Code

Number

De

fi

nition

Consequence

2

Pressure switch failed to open (stuck closed).

Wait for recovery

4

Flame current too low. Check for

fl

ame.

Non critical alarm

6

Flame sensed out of normal sequence (before opening or after closing gas valve).

Soft lockout

18

Gas valve relays welded. Five consecutive soft lockouts.

Hard lockout

23

Flame sensed during prepurge ( before gas valve signaled opened).

Soft lockout

24

Flame sensed during postpurge (after gas valve signaled closed).

Soft lockout

29

Pressure switch failed to close (Contacts stuck open)

Wait for recovery

32

Sensor 1 error. Temperature sensor in well is not reading correctly.

Verify it is connected to board. Replace if necessary.

Wait for recovery

57

Igniter

fl

ame rod shorted to burner ground

Wait for recovery

58

Igniter

fl

ame rod shorted to burner ground. Repair or replace igniter.

Wait for recovery

59

Line Voltage error - voltage out of speci

fi

cation high or low (15-37V (44-66Hz))

Wait for recovery

60

Applies only to thermostats having on-board transformer.

Polarity is wrong in this case.

Wait for recovery

Thermostat input higher than threshold.

61

Line voltage unstable - possibly too may heavy loads switching on and off causing

erratic supply voltage.

Wait for recovery

62

Soft lockout: maximum number of retries exceeded.

Soft lockout

Soft lockout is reset after one hour if alarm reason disappears.

63

Soft lockout: maximum number of recycles exceeded.

Soft lockout

64

Soft Lockout - electronics failure. On-board self diagnostics detected error.

Soft lockout

65

Over temperature error. Sensor measured temperature in excess of maximum

allowable limit.

Soft lockout

Note: Soft lockout time is 1 hour or manual reset. Hard lockout requires manual reset.

A.9 Intermittent Pilot

Ignition System Checks

STEP 1:

Check ignition cable.

• Verify ignition cable does not run in contact with metal

surfaces.

• Verify only factory supplied Ignition cable (or approved

replacement) is used.

• Verify connections to ignition module and igniter or

igniter-sensor are clean and tight.

• Verify ignition cable provides good electrical continuity.

STEP 2:

Verify ignition system grounding. Nuisance shutdowns are

often caused poor or erratic grounding.

Common ground is required for module and pilot burner/

igniter sensor.

— Check for good metal-to-metal contact between

pilot burner bracket and the main burner.

— Check ground lead from GND (BURNER) terminal

on module to pilot burner. Verify connections are

clean and tight. If wire is damaged or deteriorated,

replace with No. 14-18 gauge, moisture-resistant,

thermoplastic insulated wire with 105°C [221°F]

minimum rating.

— Check ceramic

fl

ame rod insulator for cracks or

evidence of exposure to extreme heat, which can

permit leakage to ground. Replace pilot burner/igniter

sensor and provide shield if necessary.

— If

fl

ame rod or bracket is bent out of position, restore

to correct position.

Summary of Contents for UTICA BOILERS SVB II Series

Page 23: ...23 WIRING DIAGRAMS Figure 12 Control Module Damper is not an option ...

Page 37: ...Date Service Performed Company Name Tech Initials Company Address Phone ...

Page 38: ...NOTES ...

Page 39: ...Date Service Performed Company Name Tech Initials Company Address Phone ...

Page 40: ...UTICA BOILERS 2201 Dwyer Avenue Utica NY 13501 web site www ecrinternational com ...