7

1.

Refer to local codes and appropriate ASME Boiler

and Pressure Vessel Code for additional installation

requirements.

2.

Install relief valve on 3/4” pipe nipple in tapped boiler

opening.

A. Pipe discharge line following guidelines in preceding

Warning

. See Figure 2, Page 7 .

B. Discharge line pipe size shall be equal or greater

than that of relief valve outlet over entire length

of discharge line with no intervening shutoff valve

between safety relief valve and discharge to

atmosphere.

C. Discharge line shall terminate with plain end to

atmosphere where any discharge will be clearly

visible and is at no risk of freezing.

D. Discharge line shall be independently supported to

avoid applied stress on relief valve.

E. Installation shall allow complete drainage of relief

valve and discharge line.

3.

Install Drain Valve on lower left side of boiler as

marked.

4.

Install Temperature and Pressure Gauge into ¼”

bushing threaded in tee furnished with supply piping.

See Figure 3 & 4.

5.

Connect Supply and Return Lines to boiler. See Figures

3 and 4. Connections may require certain additional

fi

ttings and parts.

INSTALLATION SYSTEM PIPING

WARNING

Burn or Scald Hazard. Discharge line shall be installed to relief valve outlet connection to avoid burns,

scalding, or water damage due to discharge of steam and/or hot water during operation.

Discharge line shall:

• connect to relief valve outlet and piped down to safe point of disposal. Check local codes for maximum

distance from

fl

oor or allowable safe point of discharge.

• be of pipe size equal to or greater than that of the relief valve outlet over the entire length of discharge

line;

• have no intervening shutoff valve between safety relief valve and discharge to atmosphere (do not plug or

place any obstruction in discharge line.

• terminate freely to atmosphere where any discharge will be clearly visible and at no risk of freezing;

• allow complete drainage of the valve and the discharge line;

• be independently supported and securely anchored to avoid applied stress on the relief valve;

• be as short and straight as possible;

• terminate with plain end (not threaded);

• be constructed of material suitable for exposure to temperatures of 375° F; or greater.

Refer to local codes and appropriate ANSI/ASME Boiler and Pressure Vessel Code, Section IV, or Boiler,

Pressure Vessel and Pressure Piping Code, CSA B51 for additional installation requirements.

!

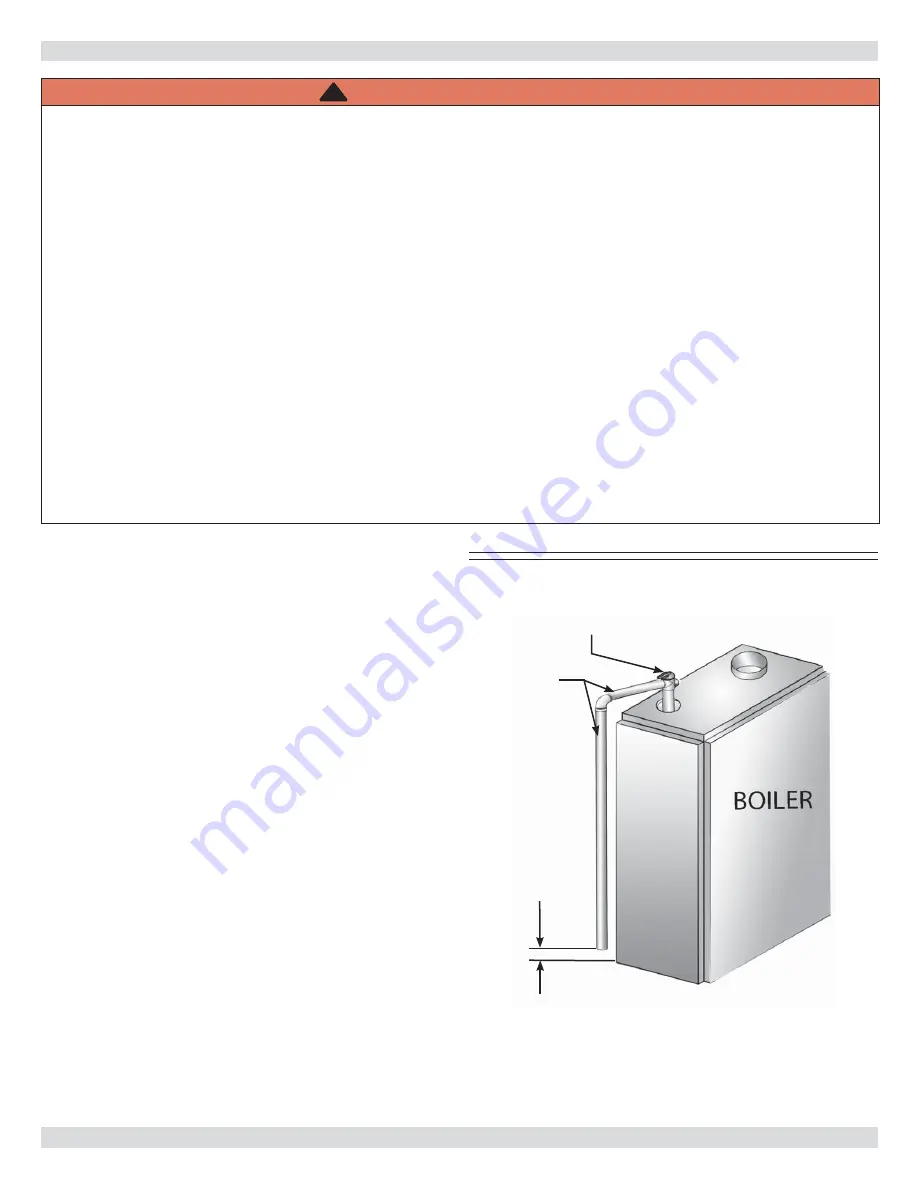

Check local codes

for maximum

distance from

fl

oor or other

allowable safe

point of discharge

RELIEF VALVE

DISCHARGE

PIPING

Figure 2 - Safety Relief Valve Discharge Piping

Summary of Contents for UTICA BOILERS SVB II Series

Page 23: ...23 WIRING DIAGRAMS Figure 12 Control Module Damper is not an option ...

Page 37: ...Date Service Performed Company Name Tech Initials Company Address Phone ...

Page 38: ...NOTES ...

Page 39: ...Date Service Performed Company Name Tech Initials Company Address Phone ...

Page 40: ...UTICA BOILERS 2201 Dwyer Avenue Utica NY 13501 web site www ecrinternational com ...