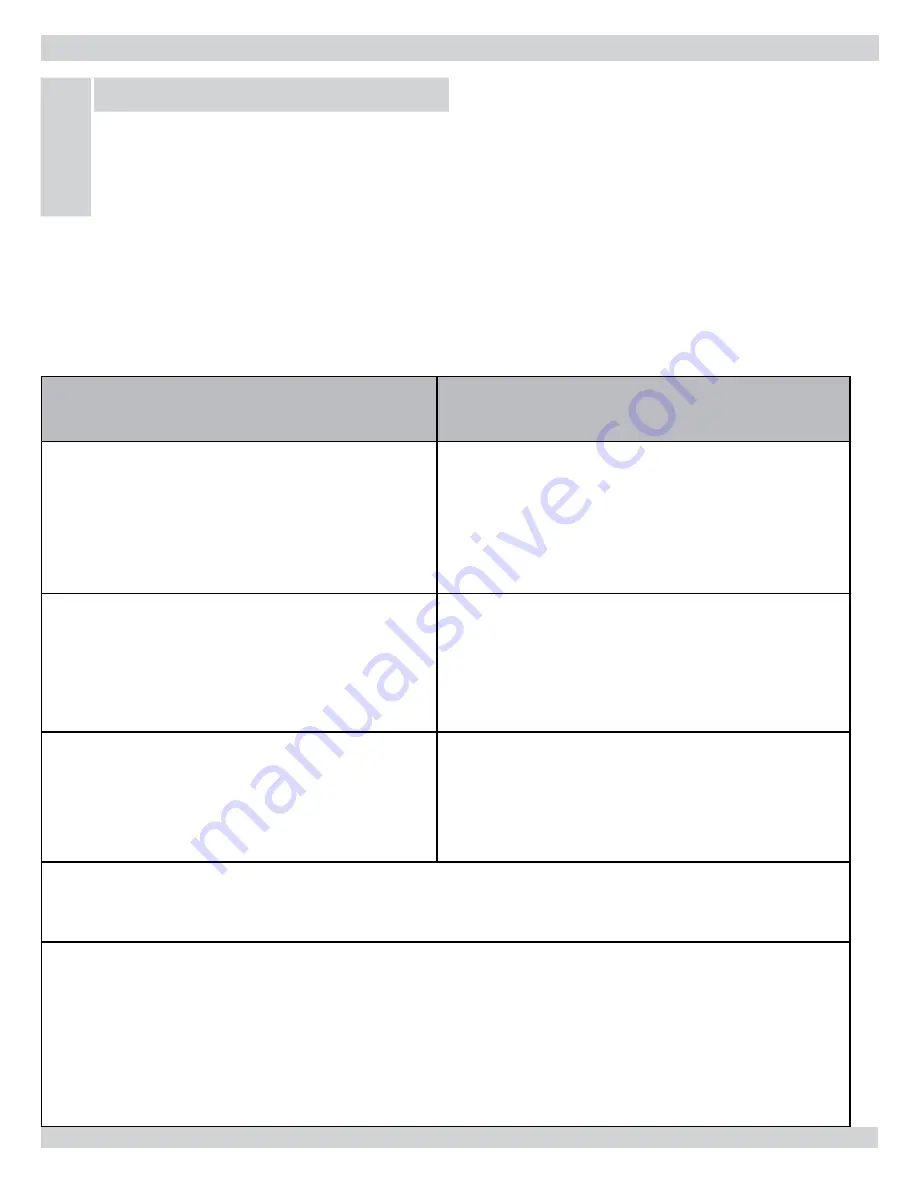

Xii - water treatment & freeze protection

Recommended Aluminum Antifreeze

& Inhibitor Suppliers

Recommended Products

Interstate Chemical

2797 Freedland Road

P.O. Box 1600 Hermitage, PA 16148-0600

www.interstatechemical.com

Tel: 800-422-2436 Fax: 724-981-8383

Intercool NFP-30,40,50 AA

Intercool RPH-15*

Noble Company

PO Box 350 Grand Haven, MI 49417

www.noblecompany.com

Tel: 800-878-5788 Fax: 800-272-1519

Noburst AL Antifreeze

Rhomar Water Management, Inc.

PO Box 229 Springfield, MO 65801

www.rhomarwater.com

Tel: 800-543-5975 Fax: 417-862-6410

Rhogard Antifreeze

Pro-Tek 922 Inhibitor*

* These products may be used to adjust the pH level of the hydronic system, but on occasion may not resolve the pH issue. In these cases it is recommended

to flush the system and refill with untreated water and new boiler manufacturer approved antifreeze suitable for Aluminum heat exchangers.

IMPORTANT

: Regardless of antifreeze or inhibitors used, be sure to follow the antifreeze manufacturer’s instructions for use, safe handling and storage of

their products. Refer to the MSDS (Material Safety Data Sheets) provided by the antifreeze manufacturer for potential hazards and first aid procedures for

exposure or ingestion.

Antifreeze Testing Services:

Each of the recommended antifreeze manufacturers have developed a sampling program available to the homeowner

and contractor. Contact the antifreeze manufacturer regarding their sampling plan procedure. Consult the antifreeze manufacturer for details on sample

requirements and recommendations.

The boiler manufacturer reserves the right to make changes without notice.

Use of antifreeze in any boiler will reduce heating capacity

•

as much as 10-20%. This must be taken into consideration

when sizing the heating system, pumps and expansion

tank. Consult antifreeze manufacturer’s literature for spe-

cific information on reduced capacity.

NOTICE

Antifreeze solutions can breakdown over time. Failure to

check antifreeze chemistry, including inhibitors, annually

may result in accelerated corrosion of boiler and other

system components. Consult with the antifreeze manufac-

turer for recommendations.

Using the antifreeze manufacturer’s instructions to deter-

•

mine the freezing temperature needed and use the correct

amount of antifreeze. Never exceed 50% antifreeze by

volume.

The boiler operating pressure must remain below 15 psi

•

for antifreeze solutions that specify a maximum of 250˚F

(121˚C).

21

Summary of Contents for UTICA BOILERS UB95M-200

Page 26: ...26 ...

Page 45: ...45 ...

Page 46: ...46 ...

Page 47: ...NOTES ...

Page 48: ...Date Service Performed Company Name Tech Initials Company Address Phone ...