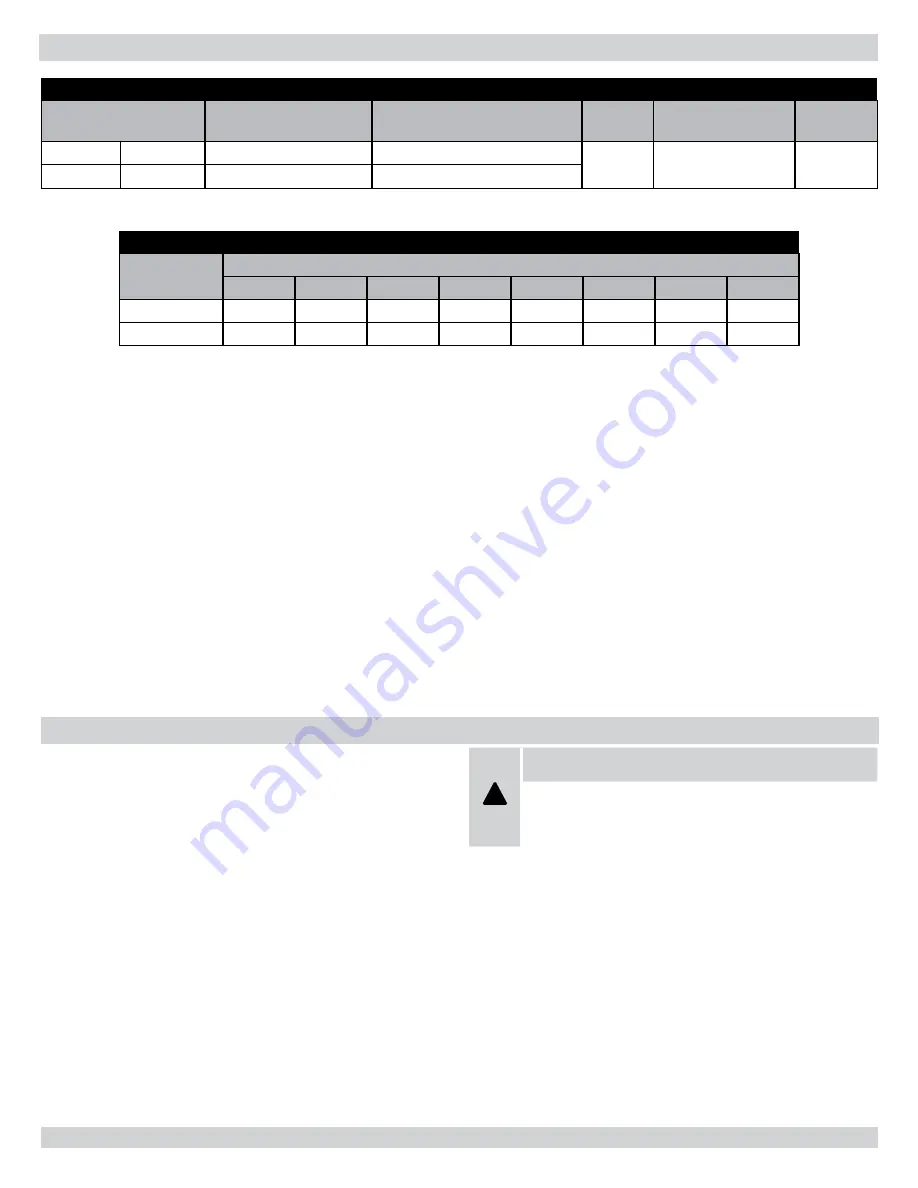

iv - boiler ratinGs and capacities

taBLE 1: SEa LEVEL RatiNGS - NatURaL aND PROPaNE GaSES

Boiler input Rate

(MBH)

(1)

Heating capacity

(MBH)

(1)(2)

Net i=B=R Rating (MBH)

(1)

aFUE

(2)

Flue Diameter

Shipping

Wt.

High Fire

200

190

165

95%

2” CPVC & 3” PVC

284 lbs.

Low Fire

80

76

66

(1)

1 MBH = 1,000 BTUH (British Thermal Units Per Hour)

(2)

Heating Capacity and AFUE (Annual Fuel Utilization Efficiency) are based on DOE (Department of Energy) test procedures.

taBLE 2: 95M-200 HiGH aLtitUDE DERatE cHaRt

Boiler input

Rate (MBH)

altitude (in Feet)

3,000 (2) 4,000 (2) 5,000 (3)

6,000

7,000

8,000

9,000

10,000

High Fire

196

192

177

174.5

172

169

168

167

Low Fire

78.4

76.8

115

113.5

112

110

109

108

1) Boiler Input Rate is determined at minimum vent length. The rate will decrease as vent length increases.

2) Parameter 17 is set to 2,250 at elevations of 2,000 feet above and below.

3) Parameter 17 must be raised to 3,200 at altitudes or elevations of 2,000 feet and above.

These low pressure gas-fired hot water boilers are design certified

by CSA International, for use with natural and propane gases. The

boilers are constructed and hydrostatically tested for a maximum

working pressure of 50 PSIG (pounds per square inch gauge) in ac-

cordance with ASME (American Society of Mechanical Engineers)

Boiler and Pressure Vessel Code Section IV Standards for heating

boilers.

The Boilers are certified in accordance with ANSI (American Na-

tional Standards Institute) Z21.13 standards as gas-fired, direct vent,

condensing, hot water boilers.

The Heating Capacity indicates the amount of heat available after

subtracting the losses up the stack. Most of this heat is available to

heat water. A small portion is heat loss from the jacket and surfaces

of the boiler, and it is assumed that this heat stays in the structure.

The Net I=B=R Rating represents the portion of the remaining heat

that can be applied to heat the radiation or terminal units (i.e., finned

tube baseboard, cast iron radiators, radiant floor, etc.) The difference

between the Heating Capacity and the Net I=B=R Rating, called

the piping and pickup allowance, establishes a reserve for heating

the volume of water in the system and offsetting heat losses from

the piping. The Net I=B=R Ratings shown are based on a piping

and pickup factor of 1.15 in accordance with the I=B=R Standard

as published by the Hydronics Institute. The Net I=B=R Rating of

the boiler selected should be greater than or equal to the calculated

peak heating load (heat loss) for the building or area(s) served by the

boiler and associated hot water heating systems. The manufacturer

should be consulted before selecting a boiler for installations having

unusual piping and pickup requirements.

in the state of massachusetts, boiler installation must conform

to state code 248 cmr which includes but is not limited to:

This product must be installed by a licensed Plumber or

•

Gas fitter.

When flexible connectors are used, the maximum length

•

shall not exceed 36 inches.

When lever type gas shutoffs are used, they shall be T-

•

handle type.

For all side wall horizontally vented gas fueled equipment installed

in every dwelling, building or structure used in whole or in part

for residential purposes, including those owned or operated by the

commonwealth and where the side wall exhaust vent termination is

review the following before installing the boiler

This boiler product is a gas-fired, direct vent, condensing boiler and

must be installed in accordance with all applicable federal, state and

local building codes including, but not limited to the following:

United States

- Installation shall conform with National Fuel Gas

Code (NFPA-54/ANSI Z223.1- latest edition)

Canada

- Installation shall be in accordance with CSA-B149.1 and

.2 installation codes

.

Where required by the authority having jurisdiction, the installa-

tion must conform to the ASME Safety Code for Controls and Safety

Devices for Automatically Fired Boilers, No.CSD-1.

The installation must conform to the requirements of the authority

having jurisdiction or, in the absence of such requirements, to the

National Fuel Gas Code, ANSI Z223.1 - latest revision.

v - before installinG the boiler

!

WARNING

Installers - Follow local regulations with respect to instal-

lation of Carbon Monoxide Detectors. Follow maintenance

recommendations in this manual.

4

Summary of Contents for UTICA BOILERS UB95M-200

Page 26: ...26 ...

Page 45: ...45 ...

Page 46: ...46 ...

Page 47: ...NOTES ...

Page 48: ...Date Service Performed Company Name Tech Initials Company Address Phone ...