27

26

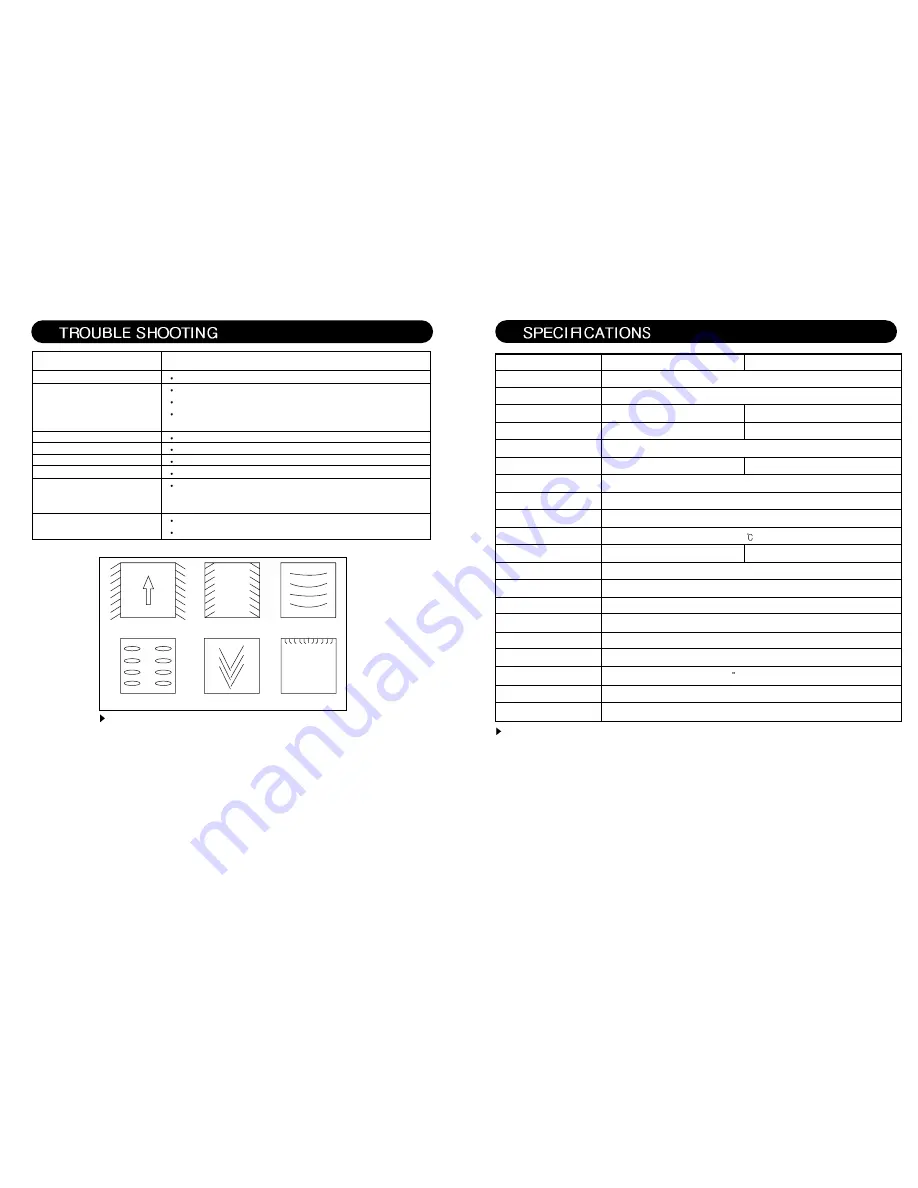

A

B

C

D

E

F

Picture A,B,C,D,E,F

Symptom Trouble shooting

Power supply problem

Rollers not turning

Symptom of picture "A"

Symptom of picture "B"

Symptom of picture "C"

Symptom of picture "D"

Symptom of picture "E"

Symptom of picture "F"

Check circuit breaker and disconnection of fuse. Contact dealer / engineer.

Check whether the front safety lever is fixed into fixing hole inside

Check safety cover is normally placed

Check roller pressure control lever position. Only when the roller pressured,

normally it works.

Increase roller pressure

Decrease roller pressure. Operate cooling fan.

Decrease roller pressure

Increase roller pressure

Operate cooling fan.

If not solved by cooling fan, cooling the laminator for about 30 minutes

This symptom caused by high temperature of pulling roller.

Operate cooling fan

Decrease roller temperature

Model Name EXCELAM-Q 1100RS EXCELAM-Q 1670RS

Power Requirements

Power Consumption

Dimensions(WxLxH)

Warm Up Time

Max Laminating Speed

Max Laminating Width

Laminating thickness

Max Mounting Height

Thickness of substrate(Paper)

Roller temperature

Weight

Heating System

Temperature Control

Temperature Adjustment

Speed Control

Type of Main Motor

Roller pressure control

Film Core

Cooling System

Rewinding Mothod

220~240V, 50/60Hz

3000W / 15A

3000mm/min

25~500mic

13mm

80~350g/m

2

160

Infrared Heater

Key Pad

Time control

Key Pad

DC Motor

Manual

77mm(3 ) Bilateral core

AC Motor (Blower fan)

Link to Main Motor

Outerior design and Product specification can be changed without previous notice.

1500 x 710 x 1250mm

22 minute

1100mm

205kg

2000 x 710 x 1250mm

25 minute

1670mm

276kg

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500