Installation / Removal / Disposal of the cartridge fi lter.

The

cartridge fi lter

holding the dust and debris must be removed and renewed by authorised personnel

only, wearing appropriate personnel protective equipment, in a specifi ed de-contamination area.

Never operate without the full fi ltration system in place.

Process of disposal:

Disconnect the hose, fi t the Dust Cap on the Hose Flange, un-clip the two Toggle Clamps.

Remove the

cartridge fi lter

from the Drum. Place the

cartridge fi lter

inside an impervious plastic bag and

seal the bag.

Dispose of the plastic bag, depending on contamination, in an appropriate manner.

24.3

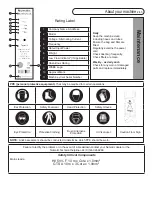

IMPORTANT USER INFORMATION

Before use operators shall be provided with information, instruction and training for the use of the

machine and the substances for which it is to be used, including the safe method of disposing of material

collected.

The cartridge fi lter has to be replaced when necessary.

This vacuum cleaner has a lamp that illuminates when air velocity drops below a preset level, which

indicates that the cartridge fi lter must be changed.

This machine is not suitable for connection with dust generating machines.

The cartridge fi lter must be undamaged and in correct position before this machine can be used safely.

WARNING:

1.

This machine must only be operated by suitably trained and authorised personnel.

2.

This machine or its accessories must not be modifi ed.

3.

The machine must not be stored or used in a wet environment.

4.

Do not allow the

cartridge fi lter to become so full as to reduce the eff ective pick-up of the

vacuum. (Lamp will illuminate at preset air velocity levels < 20 m/s).

5.

This machine must only be repaired by suitably trained and authorised personnel.

6.

Only use genuine Numatic International Ltd spare parts, for repairs.

7.

This machine must not be installed as a fi xed extraction system or run unattended.

8.

Do not re-use the essential fi lter element after removal out of the machine.

Operators should observe any safety regulations appropriate to materials being handled.

This machine is for dry use only.

PREPARATION FOR USE

Unpack and identify each item of equipment from the delivery note.

Check that the details given match the information on the “rating plate” mounted on the head assembly.

Summary of Contents for Numatic HZC 390L-2

Page 2: ...Kit AA16 2 1 3 Assembly...

Page 3: ...5 4 6 Air Diffuser Hose...

Page 7: ...3 2 1 6 5 4 9 8 7 10 11 Changing Replacing Cable...

Page 14: ...Notes...

Page 15: ...Notes...