FloormapX System Overview

33

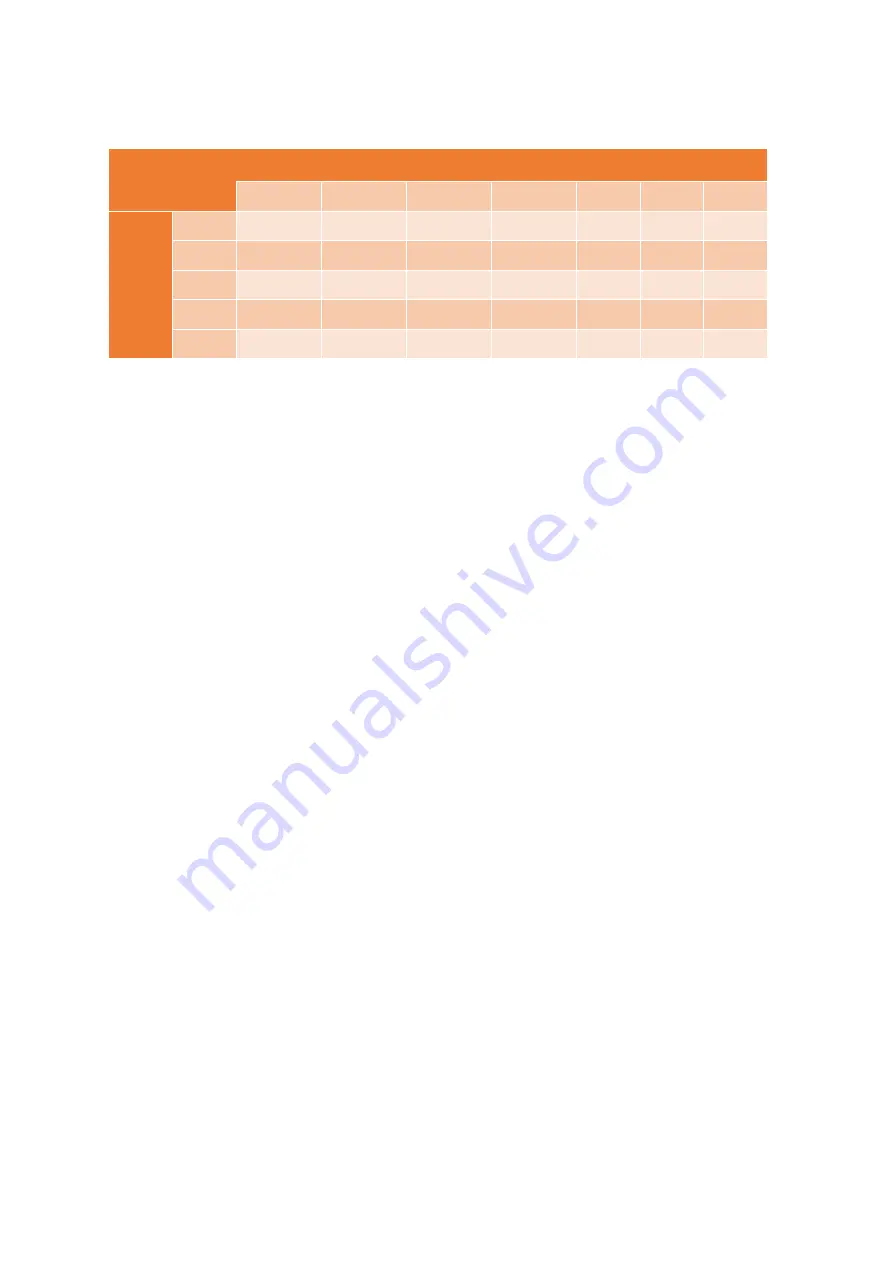

Imperial

Coating Thickness (mils)

0mils

40mils

80mils

120mils

160 mils

200mils

240mils

Pl

at

e

Thi

ckne

ss

(i

n

ch

)

1/4in

High or Low High or Low High or Low High or Low Low

Low

Low

5/16in

High or Low High or Low High or Low Low

Low

Low

Low

3/8in

High or Low Low

Low

Low

Low

Low

Low

1/2in

Low

Low

Low

Low

Low

Low

Low

9/16in +

Low

Low

Low

Low

Low

Low

Low

IMPORTANT

Operation outside the recommended specifications is possible, for example operating the

FloormapX on 16mm (5/8in) in the high position, but detection and consistency criteria

maybe adversely affected. Investigation of performance is recommended prior to inspection

to understand performance.

All calibration, especially those that are performed on plate thicknesses of greater than 12mm

(1/2in) should be verified and performance understood prior to inspection as detection and

repeatability may be affected.

It is recommended to include a scan overlap for inspections that are to be performed on plate

thicknesses of greater than 12mm (1/2in).

2.5

MFL Technique

To detect a leaking field, the FloormapX uses hall effect sensors mounted between the poles of a

magnetic bridge. The magnetic bridges include strong permanent magnets that induce a magnetic

field into an inspection specimen. The presence of a defect in the inspection specimen causes the

induced magnetic field to leak and it is this leaking magnetic field that the suitably placed hall effect

sensors detect.

MFL systems are heavily reliant on the inspection surface, upon which they operate. It is important

to understand that as the condition of the inspection surface deteriorates, so can the effectiveness

of any MFL system. All MFL systems interpret a leaking field and any influencing factors that affect

this leaking field must be understood and factored into the inspection process.

As MFL can, in part, be considered as a volumetric detection technique, it is important to understand

the relationship between the calibration defects and defect depth. In cases where accurate remaining

wall thickness is required, any defect indications reported with the FloormapX system should be cross-

checked with an alternative method (such as UT or a pit gauge).

Summary of Contents for Floormap X

Page 1: ...User s Manual Floormap X MFL Array Tank Floor Inspection Solution...

Page 10: ...10 Chapter 1 Precautions and conventions...

Page 16: ...General Precautions and Conventions 16 1 5 EU Declaration of Conformity...

Page 19: ...19 Chapter 2 FloormapX System Overview...

Page 35: ...35 Chapter 3 Inspection Preparation Setup and Operation...

Page 43: ...43 Chapter 4 SIMS GO Data Acquisition Software...

Page 69: ...69 Chapter 5 SIMS PRO...