- 2 -

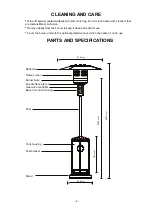

HEATER STAND AND LOCATION

The heater is primarily for outdoor use only. Always ensure that

adequate fresh air ventilation is provided.

Always maintain proper clearance to combustible materials, i.e. top 100 cm

and sides 100 cm minimum.

Heater must be placed on level firm ground.

Never operate heater in an explosive atmosphere like in areas where

gasoline or other flammable liquids or vapors are stored.

To protect heater from strong wind, anchor the base securely to the

ground with screws.

GAS REQUIREMENTS

Use propane or butane gas only.

The pressure regulator and hose assembly to be used must conform to local standard codes.

The installation must conform to local codes, or in the absence of local codes, with the standard for the

storage and handling of liquid petroleum gases.

A dented, rusted or damaged propane tank may be hazardous and should be checked by your tank

supplier. Never use a propane tank with a damaged valve connection.

The propane tank must be arranged to provide for vapor withdrawal from the operating cylinder.

Never connect an unregulated propane tank to the heater.

LEAKAGE TEST

Gas connections on the heater are leak tested at the factory prior to shipment. A complete gas tightness

check must be performed at the installation site due to possible mishandling in shipment or excessive

pressure being applied to the heater.

Make a soap solution of one part liquid detergent and one part water. The soap solution can be applied

with a spray bottle, brush or rag. Soap bubbles will appear in case of a leak.

The heater must be checked with a full cylinder.

Make sure the safety control valve is in the OFF position.

Turn the gas supply ON.

In case of a leak, turn off the gas supply. Tighten any leaking fittings, then turn the gas supply on and re-

check.

Never leak test while smoking.

CEILING

W

A

L

L

100 cm

100 cm

Fortification of base to the ground

LO

HI

Off

Igniter

Pi

lo

t