409001_01 | 12.2020

Attachments with chain drive

22

EN

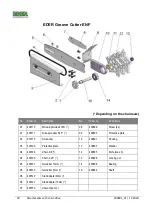

Fig. 8:

Cutting depths on the knife gauge

The smaller the knife protrusion, the less wood is removed and the

smoother the surface becomes.

> Loosen the knife screw (

1

- Fig.9).

> Push the knife (

2

– Fig.9) all the way back.

> Place the knife gauge (

3

– Fig.9) on the cylinder (

4

– Fig.9) so that it

rests on the two bearing surfaces of the cylinder at the top and

bottom.

> Push the knife onto the knife gauge until the desired setting height

(0.2 mm, 0.4 mm, 0.6 mm) is reached.

> Retighten the knife screw. Tightening torque: 35 Nm

EDER Groove Cutter ENF-C

Sharp knives are required for optimal work with the EDER groove cutter

ENF-C.

Up to three knives can be fitted to vary the cutting width.

>

Loosen the nut and put the desired number of knives on the shaft.

>

The knives can be resharpened several times.

>

Put the washer and the nut on the shaft

>

Tighten the nut again to 35Nm.

i

Fig. 9

Knife adjustment

1

2

4

3