27

Eder Forestrytools

310003_04 | 06.2019

Adjust the knives from case to case.

The smaller the knife protrusion, the less wood is removed

and the smoother the surface becomes.

Fig. 9:

Knife adjustment

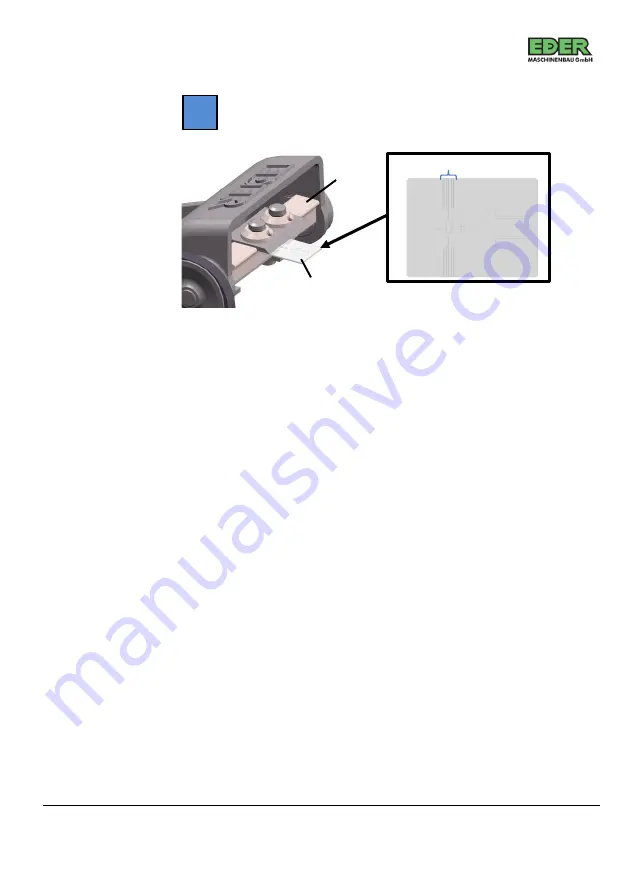

The tungsten carbide pins on the knife discs serve as depth limiters.

All four knives must therefore have the same setting and the same

distance to the carbide pins. The knives must not protrude beyond

the tungsten carbide pins.

All four knives are replaced and adjusted in the same way. Proceed

as follows for each knife:

> Loosen the Allen screw of the knife with a 6 mm Allen key.

> Replace the knife if necessary.

> Push the setting gauge (

2

) under the knife in the direction of the

arrow up to the peeling cylinder (

1

).

> Push the knife back or forward until the cutting edge touches the

zero mark.

If the device cuts too deeply or even chops:

> Move the knife in negative direction.

If the cutting depth is too shallow:

> Move the knife in positive direction.

Attention:

The cutting edge of the knife must be within the marked

area (

3

).

> The tungsten carbide pin on the knife disc must always be

pointed forward, towards the cutting edge.

> Retighten the Allen screw of the knife.

Tightening torque: 35 Nm

i

3

2

1