U.S.A.

Jabsco

20 Icon

Foothill Ranch, CA 92610-3000

Tel:

949.609.5106

Fax: 949.859.1254

UNITED KINGDOM

Jabsco

Bingley Road, Hoddesdon

Hertfordshire EN11 OBU

Tel:

+44 (0) 1992 450145

Fax: +44 (0) 1992 467132

CANADA

Fluid Products Canada

55 Royal Road

Guelph, Ontario N1H 1T1

Tel:

(519) 821.1900

Fax: (519) 821.2569

JAPAN

NHK Jabsco Company Ltd.

3-21-10, Shin-Yokohama

Kohoku-Ku, Yokohama, 222

Tel:

045.475.8906

Fax: 045.475.8908

GERMANY

Jabsco GmbH

Oststrasse 28

22840 Norderstedt

Tel:

+49-40-53 53 73 -0

Fax: +49-40-53 53 73 -11

THE PRODUCTS DESCRIBED HEREIN ARE

SUBJECT TO THE JABSCO ONE YEAR LIMITED

WARRANTY, WHICH IS AVAILABLE FOR YOUR

INSPECTION UPON REQUEST.

© Copyright 2003, ITT Industries

Printed in U.S.A.

All Rights Reserved

Form: 43000-0753

Rev. 05/2003

TROUBLESHOOTING

PULSATING FLOW – PUMP CYCLES ON AND OFF

Restricted pump delivery. Check discharge lines, fit-

tings and valves for undersizing or clogging. Clean

screens in faucets. Some filters or purifiers are highly

restrictive. Filters/purifiers with high pressure drop may

require a separate line and the installation of an accu-

mulator tank in the system.

FAILURE TO PRIME – MOTOR OPERATES, BUT NO

PUMP DISCHARGE

Restricted intake or discharge line.

Air leak in intake in line.

Punctured pump diaphragm (water leak).

Debris under flapper valves.

Crack in pump housing.

MOTOR FAILS TO TURN ON

Loose wiring connection.

Pump circuit has no power.

Blown fuse/Thermal Protector tripped (wait 30 min.).

Pressure switch failed.

Defective motor.

PUMP FAILS TO TURN OFF AFTER ALL FIXTURES

ARE CLOSED

Empty water tank.

Punctured pump diaphragm (water leak).

Discharge line leak.

Defective pressure switch.

Insufficient voltage to pump.

Debris under flapper valves.

LOW FLOW AND PRESSURE

Air leak at pump intake.

Accumulation of debris inside pump and plumbing.

Worn pump bearing (excessive noise).

Punctured pump diaphragm (water leak).

Defective motor.

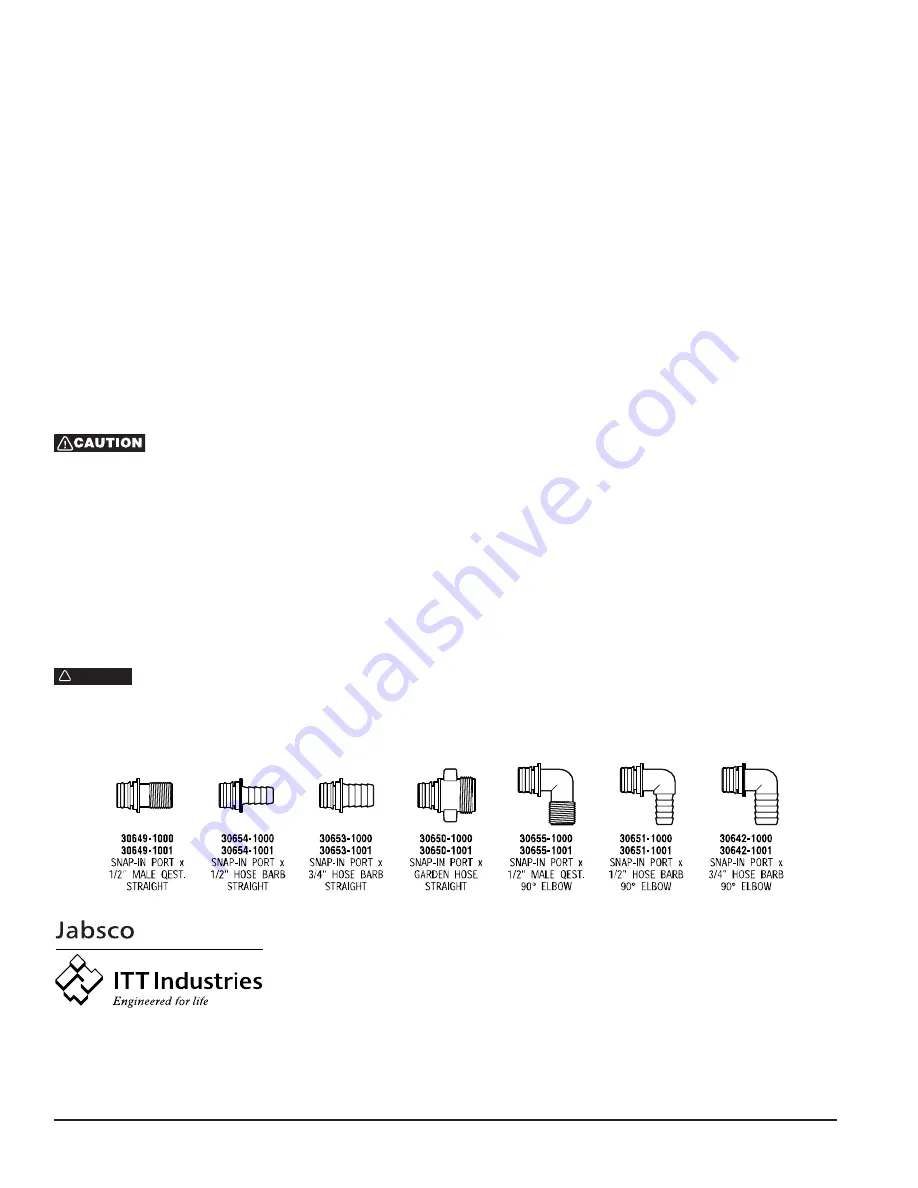

ACCESSORIES

SNAP-IN PORT SYSTEM

WINTERIZING YOUR WATER SYSTEM

To winterize, it is not necessary to drain the water from

the entire water system. Blowing into the lines to remove

the water from your water system is not satisfactory due

to the check valve mechanism built into the pump.

Follow these steps to remove all water from your water

system:

1. Drain water by opening tank drain, or open a fixture to

allow pump to operate until tank is dry.

2. Open the lowest outlet in water system to drain lines.

3. To remove any remaining water (about a cup), remove

outlet hose on pump and activate pump. To blow out

lines, attach air nozzle where outlet hose was

removed. Make sure all fixtures are open before starting.

4. Your water system is now winterized. Don’t forget to

reattach the outlet hose to pump and close all fixtures.

PAR-MAX pumps have thermal overload protected motors. The motor will automatically shut off as

temperature rises due to an overload condition. If the motor shuts off in this manner, close all nozzles, faucets or

valves. After a cooling off period, the pump will automatically re-start.

DO NOT USE AUTOMOTIVE TYPE ANTI-FREEZE. IT IS POISONOUS. USE OF THIS TYPE ANTI-

FREEZE WILL CAUSE SERIOUS INTERNAL INJURY OR DEATH.

DANGER

!

Summary of Contents for 190 InShore 2014 Series

Page 1: ...190IS 190 InShore Series OWNER ASSISTANCE MANUAL Revised 2014...

Page 30: ...28 Appendix 190 IS...

Page 31: ...29 Hydraulic Steering System...

Page 32: ...30...

Page 33: ...31...

Page 34: ...32...

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 52: ...vi Selection Guide...

Page 58: ...1 6 Selection Guide...

Page 62: ...2 4 Selection Guide...

Page 88: ...4 8 Selection Guide...

Page 138: ...11 2 Selection Guide...