7

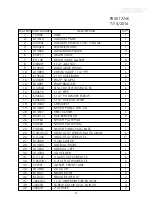

MACHINE SPECIFICATIONS

PUMP:

submersible, Epoxy-coated steel construction, Nylon Im-

peller, 50 GPM. Handles spherical solids up to ½”.

VACUUM:

5.7” 3 stage, high performance

AIR WATTS:

601

AIR FLOW:

110

WATERLIFT:

158”

VACUUM OVERFILL FLOAT SWITCH:

Yes, tilt type float switch

LARGE TANK OPENING:

Yes

HOSE DIAMETER:

1.5” vacuum, 1.5” discharge

REAR WHEELS:

12” Ball Bearing, Non-Marking

FRONT CASTERS:

5” Locking

POWER CORD:

Detachable 12 GA x 25 ft, Twist lock

POWER CONSUMPTION:

120V, 18 Amps

MACHINE WEIGHT:

106 lbs

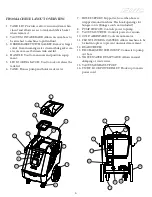

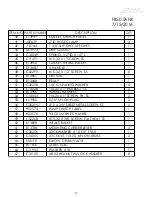

SETTING UP THE MACHINE BEFORE

OPERATION:

1. Position the machine on a dry place away from the

flooded area. Lock in the casters so that machine does

not change position during operation.

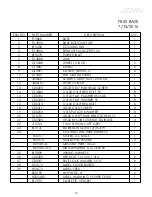

2. Connect your discharge hose (#2 on page 5) to the

discharge hose hookup on the machine (#13 on page

6).

3. Position the end of the discharge hose in a safe drain-

age location. Check local laws and regulations for

proper waste water disposal.

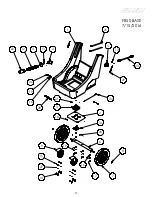

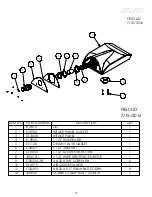

4. Make sure the debris basket with gasket (#3 on page

4) is in place before you position the lid (#1 on page 4)

on the tank. Without the debris basket in position, the

vacuum motor will not create suction.

5. Make sure to tuck the lip on the lid under the metal

bracket

6. Turn the lid locking latch to the closed position.

7. Check on the drain valve and make sure it is fully

closed position.

8. Connect your vacuum hose (#1 on page 5) to the

vacuum intake barb (#2 on page 6).

IMPORTANT:

To ensure a secure lock on the lid:

1. Make sure the lip on the lid is tucked under the metal

bracket.

2. Pivot the lid locking latch (#5 on page 4) over the lid.

Note: To prevent the lid from being lost,

the above steps should also be followed when

transporting the equipment, especially in open air ve-

hicles or trailers.

Summary of Contents for FLOODBUSTER FB50

Page 10: ...9...