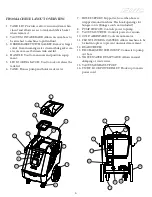

OPERATION OF THE MACHINE:

1. Turn on both vacuum and pump switches. Vacuum

motor will turn on immediately and start pulling

water inside the tank. The pump will not start dis-

charging water until a certain level of water is reached

and the float switch is activated.

2. For deep flooding, you may submerge the end of the

vacuum hose directly into the flooded area. Continue

extracting until the flooding is low enough to use the

appropriate hard floor or carpet tool.

3. For hard floors, attach the squeegee head to the wand

and vacuum hose. Use the wand to recover as much

fluid as possible.

4. For carpets, connect the scallop tool to the wand and

vacuum hose. Use scallop tool and wand to recover as

much fluid as possible.

5. Continue the operation until the task is complete.

Note:

During operation, it is normal for both the

vacuum motor and pump are designed to start and stop

automatically as the float switches regulate the level of

water in the tank.

AFTER OPERATION:

1. remove the hoses and run the vacuum motor for a

minimum of three minutes with only air moving

through the system. Doing so will ensure all mois-

ture is removed from the vacuum system. Residual

moisture in the system may damage the vacuum

motor.

2. Turn off the switches and unplug the power cord

from the machine power inlet and also from the wall

power outlet.

3. Dump the water remaining in the tank after opera-

tion.

4. Rinse the tank with clean water.

5. Drain the tank completely.

6. Detach the hoses from the machine.

TROUBLE SHOOTING:

No user serviceable parts. Any inspection or service

should be conducted by a technician at an approved

service station.

Contact EDIC for assistance in locating an approved

service station.

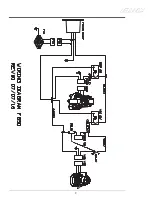

PUMP DOES NOT DISCHARGE LIQUID:

• Machine is not plugged in.

• The switch is not on.

• The switch is bad.

• The float has debris accumulated on it.

• Float or float rod has obstruction.

PUMP DOES NOT SHUT OFF:

• The pump is air locked. Turn off the pump switch for

a minute and turn it on again. Repeat the procedure

until the air is completely out.

• Float or float rod has obstruction.

• Impeller Inlet plugged. Have service station clean the

pump.

WEAK SUCTION FROM THE VACUUM

MOTOR:

• Lid is not completely closed.

• Debris basket is missing or not in proper position.

• Drain Valve is open.

• Wand is plugged.

• Vacuum Hose leaks.

VACUUM MOTOR DOES NOT TURN

ON:

• Machine is not plugged in.

• The vacuum motor switch is not on.

• The switch is bad.

• The vacuum float switch is stuck in high position.

• Connection on the relay is bad.

VACUUM MOTOR DOES NOT SHUT

OFF:

• The vacuum float switch is stuck in low position.

• Relay contact is stuck shut.

8

Summary of Contents for FLOODBUSTER FB50

Page 10: ...9...