Status, Error, and Service Messages

123

Service Messages

A service message sometimes occurs as a result of an unusual combination

of events, not because of an actual problem. When the printer stops and a

service message displays in the message window, turn the printer off and

then back on. This often clears the service message indicator, and printer

operation resumes. Always try this before making a service call.

Service calls should be placed to the vendor from whom you purchased the

printer. If you cannot get service from your vendor, see the

Service & Support

Guide

for additional contact information.

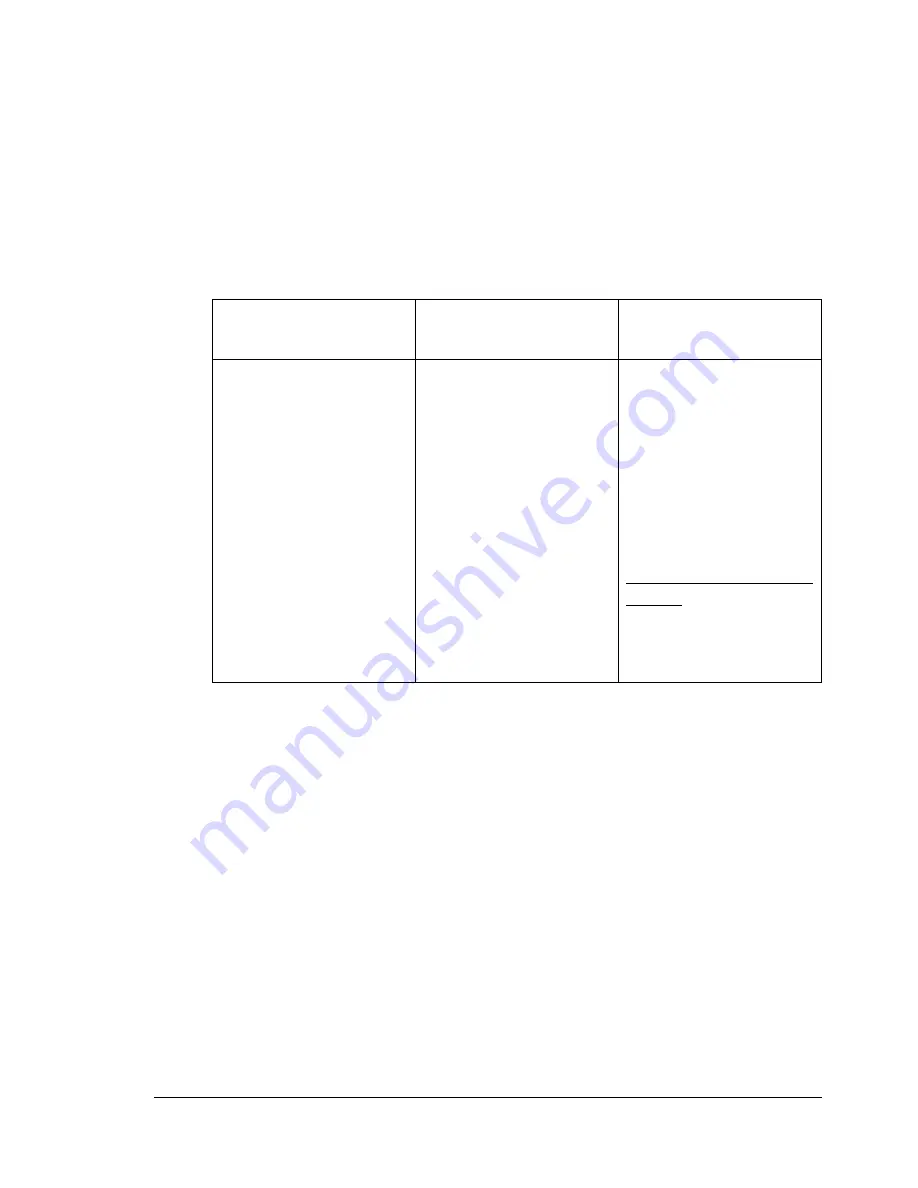

This service

message...

means...

do this...

CALL FOR SERVICE

<X>

An error has been

detected with the item

indicated

<X>

in the

service message.

Reboot the printer. This

often clears the service

message indicator, and

printer operation can

resume. If the condition

persists, contact your

local vendor or check

the

Service &

Support Guide

or

www.konicaminolta.net/

printer/ for information

on KONICA MINOLTA-

authorized service

providers.

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Summary of Contents for Magicolor 3300

Page 1: ...magicolor 3300 User s Guide 1800738 001A EDNord Istedgade 37A 9000 Aalborg telefon 96333500 ...

Page 9: ...Software Installation EDNord Istedgade 37A 9000 Aalborg telefon 96333500 ...

Page 20: ...EDNord Istedgade 37A 9000 Aalborg telefon 96333500 ...

Page 21: ...Using Media EDNord Istedgade 37A 9000 Aalborg telefon 96333500 ...

Page 52: ...EDNord Istedgade 37A 9000 Aalborg telefon 96333500 ...

Page 53: ...Color Printing EDNord Istedgade 37A 9000 Aalborg telefon 96333500 ...

Page 59: ...Replacing Consumables EDNord Istedgade 37A 9000 Aalborg telefon 96333500 ...

Page 78: ...EDNord Istedgade 37A 9000 Aalborg telefon 96333500 ...

Page 79: ...Maintaining the Printer EDNord Istedgade 37A 9000 Aalborg telefon 96333500 ...

Page 87: ...Troubleshooting EDNord Istedgade 37A 9000 Aalborg telefon 96333500 ...

Page 135: ...Installing Accessories EDNord Istedgade 37A 9000 Aalborg telefon 96333500 ...

Page 159: ...Technical Specifications EDNord Istedgade 37A 9000 Aalborg telefon 96333500 ...

Page 198: ...EDNord Istedgade 37A 9000 Aalborg telefon 96333500 ...